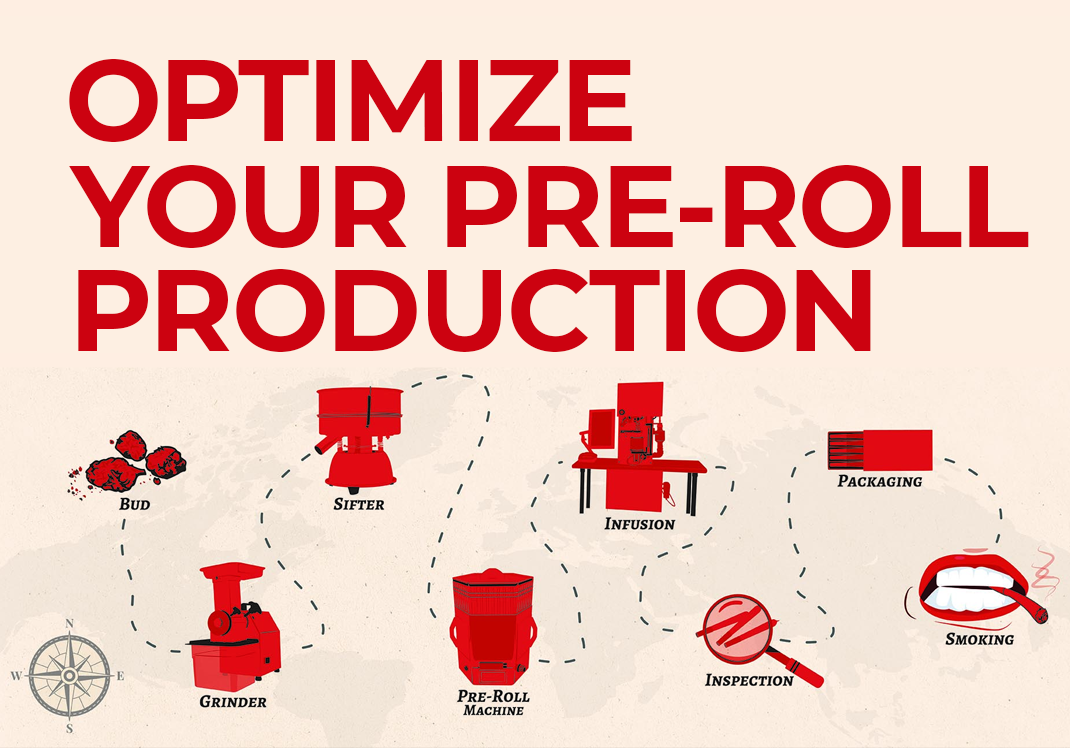

10 Steps to Perfect Your Pre-Roll Production

Posted by Custom Cones USA on Dec 22nd 2020

Updated: June 14, 2024

Producing the perfect pre-roll joint or blunt can sometimes seem like chasing after the Holy Grail.

With so many small mistakes that can happen along the way, you can ruin the pre-roll before it even gets to your clients if you are not focused on your pre-roll production process. Fortunately, there's a solution. Utilizing quality pre-roll machinery has been proven to improve not only how pre-rolls smoke, but also boost the bottom line for companies.

By using the following steps, you can expedite your pre-roll production without sacrificing the overall quality. These tips and tricks will guide you from the beginning of your production process all the way to the delivery of the boxes to the retailers. With these processes in place, there is no doubt that you will be able to deliver the highest quality pre rolled cones to consumers, as well as avoid common pitfalls.

1. Carefully Grind Your Material

After using a bucker and trimmer to separate the buds, the first step in the pre-roll process is to grind the material. This is, arguably, the most important step because if the grind is done incorrectly, the final product will be sub-par and all the hard work during the harvest will be wasted.

Many grinders use high-RPM systems with blades that pulverize the material into powder. This is counterproductive for pre-rolls because it increases the likelihood of an uneven burn once packaged into a pre-roll cone or tube. Furthermore, most of the kief – made of trichomes (which produce cannabinoids and terpenes) – is separated from the plant when ground this fine, which reduces flavor and potency. A high-RPM grinder is really only good for making extraction products.

Instead, we highly recommend Industrial Cannabis Grinder and Industrial Cannabis Grinder XXL because they use a high torque, but low-RPM motor system to push the material through the particle screens, instead of actually shredding the material. Since the material is pushed through the screens, the consistency is uniform. To keep things flexible, the grinder comes with three particle screen sizes, enabling you to fine-tune the grind to suit your needs

The Industrial Cannabis Grinder can easily grind a pound per minute and creates a perfect grind for pre-rolls, while the XXL version can grind 300-600 pounds per hour. The low-RPM design on both machines also helps mitigate heat generation, which can degrade both terpenes and cannabinoids. Plus, since the material is pushed through the screens, the consistency is uniform. And to keep things flexible, the grinder comes with three particle screen sizes, enabling you to fine-tune the grind to suit your needs.

There is also the Grindsizer 3, a pharmaceutical grade grinder that can be tuned to produce the exact particle size and distribution you need. Featuring milling and blade technology from Fritch, the leading German milling manufacturer, the GrindSizer 3 can process one to three pounds per minute, depending on the strain and moisture content. The GrindSizer 3 is an excellent choice for manufacturers utilizing automated pre-roll machines, due to the extreme precision and pharma-grade requirements. And with a few additions, the GrindSizer 3 can be fitted directly to your sifter or automated pre-rolled cone filling machine. Call the Pre-Roll Experts today for more information.

2. Sift Out Stems and Any Unwanted Materials

A step often missed before packing the flower into pre-roll cones is sifting the stems and unwanted material after the grind. Sifters come with a variety of mesh screen sizes that help sift out bigger stems or even sift out kief without losing any of it.

Currently, we have three recommended sifters: Quick Sift, Commercial Sifter, and the Quick Sift Mini, offering a range from smaller/budget friendly to larger/commercial options. Each sifter has different screen grades.

Since the sifter takes out all the stems, the material put into the pre-rolls is only the premium material, a fact that undoubtedly leads to long-term sales and customer loyalty. Recent posts on Instagram have exposed brands with huge stems in their pre-rolls because no consumer is trying to smoke that. The introduction of affordable, high volume sifters will help these companies to more easily take the extra step to improve quality without hurting profit margins.

3. Pack Cones with a Cone Filling Machine

The first thing to note before we jump into packing our cones with our premium grind is that if you are NOT sifting, the material needs to stand out for about six-eight hours to decrease the moisture by approximately 10-12 percent.

This is a pivotal step to ensure that the flower is not sticky and therefore much harder to package into pre-roll cones. Additionally, this step prevents the oils that have been activated in the grind from seeping through the paper, which happens often when cone-packing is rushed. We can reintroduce moisture in a later step.

OK, back to cone filling machines! Over the past couple years, there has been an increase in the production of many new pre-roll packing machines known as cone filling machines. These machines can range greatly in price and each have their own benefits.

For example, you can then choose from machines like the King Kone orFill N Fold to fill your pre-roll cones. These machines use strong motors to vibrate the flower down from the top, and with additional attachments, like the tamper tool, you can create a perfect pack.

You can also further upgrade to a semi-automatic and fully automatic pre-roll machine, which packs the cone, weighs it, and even twists/folds the top of the cone. These cones pack perfectly and offer some of the slowest burning sessions ever. If your team is at 50,000-100,000 cones per month, this is the ideal machine to take your pre-roll production to the next level.

4. Make an Assembly Line with WIP Trays

4. Make an Assembly Line with WIP Trays

After you finish packing your cones, if your team does not have an automatic machine, you need to begin to take each joint out from each of the slots in the pre-roll loading tray. After this, your team has an assembly line to weigh the joint for compliance and then twist/fold the top before it goes into the final pre-roll package like a doob tube or multipack.

Since this step takes so much time, it’s important to streamline it. This is where the Work-in-Progress (WIP) trays come into play. You can place the joints on these trays once they have been weighed, and then pass a whole tray to the next step in the production process. With each team member specialized in their specific task, the quality is much higher and the throughput increases dramatically.

We highly recommend taking a look at getting bulk trays for your team, which is also great for any manual kief coating you want to do for your pre-rolls.

5. Use Humidity Packs to Restore Moisture

After packaging, the humidity packs are an important step to the pre-roll process because keeping the flower fresh is everything to consumers. If the pre-rolls are not packaged immediately, then they need to go into an air-tight container with a humidity pack from Integra or Boveda, so you can keep the pre-rolls fresh.

Many companies are also taking notice that even after you have packaged the pre-rolls, you can add a humidity pack into your multi-pack or single pack to further maintain the freshness when it reaches the consumers hands. While it does increase the cost per unit, the long-term effects it has on your brand and overall sales are dramatic because repeat customers want to trust that their favorite brands are the highest quality. You can read more on how the moisture levels do have a huge indirect effect on the bottom line.

6. Use a Direct Thermal Printer for Batch Info Details

The next step is to prepare any batch information that needs to go onto the package. In order to save money, you can use a printer that is able to do direct thermal printing, instead of ink printing. These label printers only print black and white but that is all that is needed to print out the compliance data.

Another new innovation has come out is that you can get the sticker labels that go on tubes and boxes with the thermal coating built in. This enables you to put fully customized labels into a direct thermal printer and print the batch info in a designated spot on the label. The money saved here is incredible because you no longer need to get blank stickers, plus it saves time because you can do both steps at the same time.

7. Choose the Correct Pre-Roll Packaging

Now that the batch info is ready and the pre-rolls are ready to be packaged, the next step is to choose the right pre-roll packaging to ensure compliance. In the cannabis industry, you will need child-resistant packaging (CR) in most states, and likewise a tamper-resistant finish on the top. In the hemp industry, the CR packaging is not needed, so there are more options for this.

You can find the right packaging by asking yourself two questions: Is it user-friendly to open? Is it easily customized?

For single pre-rolls, a popular option is the plastic pop top tubes or the glass pre roll tubes, while boxes are usually used for multipacks. The right size also matters. Most cones come aligned with the following stock sizes: 109mm (full gram), 98mm (.7 gram), 84mm (half gram), and 70mm (mini Dogwalker cone). If the wrong package is chosen, it could potentially not fit correctly. Many people also package the joints too tight or loose, causing the material to fall out of the cone. This is the first impression you don’t want to make.

The packaging also needs to be sturdy to protect the joints on the go. This especially goes for multi-packs which consumers carry around in their pockets. The source of the packaging material is equally important because this feeds into the type of branding you want to accomplish. You can go the environmentally friendly route with recyclable tubes, ocean plastic tubes, or paper boxes. The most affordable option is plastic, of course, but it’s also less popular with younger customers.

8. Label and Make Package Tamper Evident

Now that the pre-rolls are in the packaging, an important step is to label your pre-roll with a sticker label (if no shrink sleeve is used) and also use a shrink band or sticker to make the package tamper evident. In most states, this is needed to show that no one has opened the package after it’s been sealed

As a more affordable option, a shrink band can be placed on the tube with a heat gun. You can also upgrade this process by using a shrink sleeve machine or heat tunnel to shrink the bands at a higher pace. The sticker tamper evident stickers are more premium and also offer an option to customize the sticker to further get your branding message out.

For the sticker label, you use labeling machines to apply it onto the joint tubes and also on any box packaged. The sticker labels give versatility, instead of direct printing, as you can change your strain selection faster or any information on the fly.

9. Seal Packaging with a Heat Sealing Machine

Now that you are packaged and labeled, the next step if it’s a box would be to seal them with cellophane wrap, to make them airtight. If the above step of putting a humidity pack is also done, it’s even more important because it ensures that the first smell the consumer gets when they rip open the cellophane is pure freshness.

Making each box airtight seal also protects the pre-rolls from the climate, which can be intense in states like Florida and Arizona.

10. Place the Packages into Retail Boxes

Now that all in-house steps to package the pre-rolls are complete, you can put each package in their individual point-of-purchase (POP) retail display box. These boxes make it easier to send to the retailer and sell your product much faster since they act like billboards right in front of the customer.

The retail boxes also protect the pre-rolls when they are in transit to the retailer, which ensures that all the time that was taken to get to this step was not in vain. You can have these retail display boxes customized with the barcodes already on the box, saving your team time in labeling the box and letting the retailer track inventory much more easily.

We highly recommend doing a retail box for single options or multi-packs because the consumer wants options and often makes impulse buys when they are at the dispensary counter.

Elevate Your Pre-Roll Production Today

We hope that these steps will improve quality and further push the market to raise the bar on how pre-rolls should be delivered to customers. By following these steps, you will not only save on cost, but also have your long-term branding in place to dominate the growing market. These steps are also a reminder that it’s better to invest in efficient machines that last, instead of purchasing machines that save you money now but end up costing you more in labor and time.

Most importantly, it’s a reminder that cutting corners in the pre-roll production process only leads to poor quality joints. With more competition, consumers will steer away from sub-par joints on the shelves.

If you're interested in leveling up the quality and quantity of your pre-rolls, we’d love to have a discussion. As the pre-roll experts, our goal is to help brands and foster the pre-roll industry in an effort to raise standards in the market. Contact us to start a conversation and learn how you can elevate your pre-roll production today.