Automated Pre-Roll Machines

Automated Pre-Roll Machines

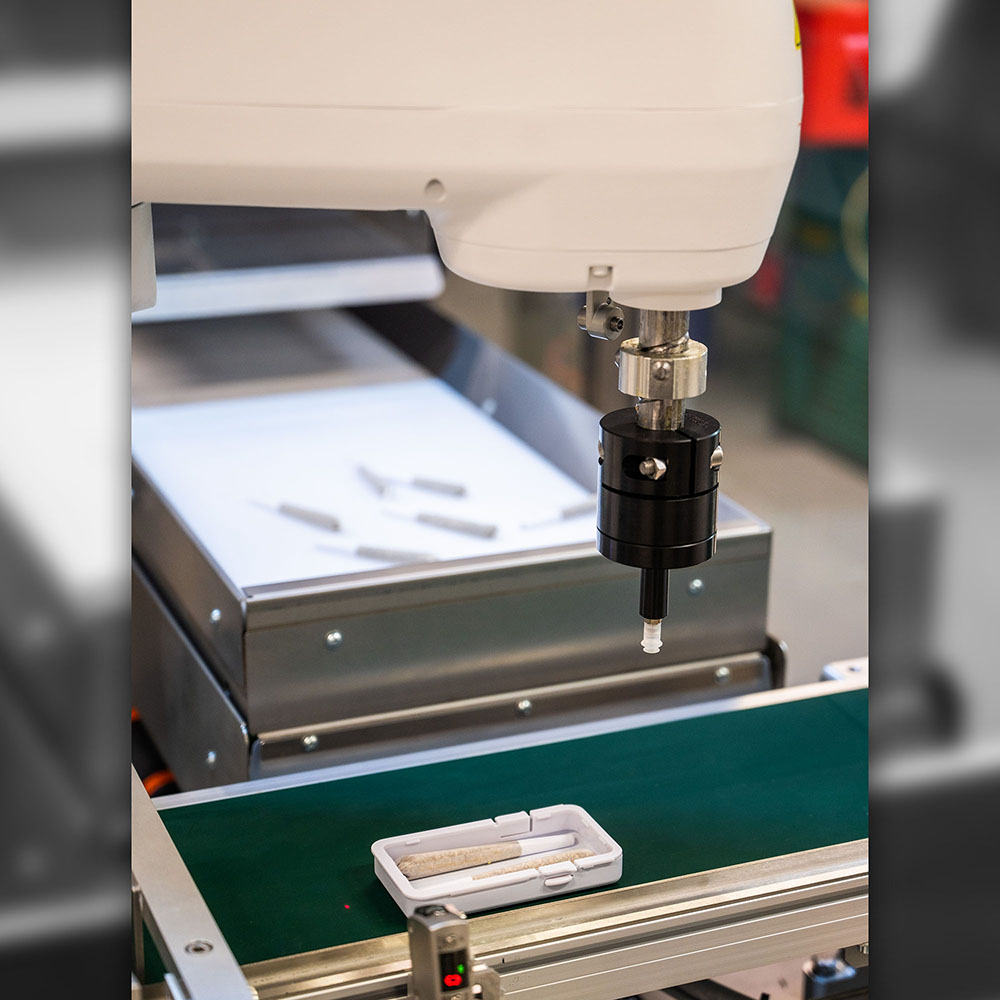

We offer multiple sizes and types of automated pre-roll machines from multiple engineering firms, so you can trust us as we guide you through the pre-roll automation process. Our team has been involved in pre-roll automation since the beginning, so we know the ins and outs of all the machines and the entire pre-roll manufacturing process in general. Automated pre-roll machines can fail due to many variables – like the particle size of the flower, to the moisture content, to the pre-rolled cones, and even the temperature of the room the automated pre-roll machine is operating in. You can trust us, as our team of experts has helped brands of all sizes responsibly scale and automate their pre-roll process.

Get 50,000 Free Pre-Rolled Cones with the purchase of an Automated Pre-Roll Machine!*

Some restrictions apply. See details below or please contact us to learn more.

Promotion Details: 50,000 Free Cones with Automated Pre-Roll Machine Purchase

*Qualifying automated pre-roll machine purchases must be made through Custom Cones USA and the 50,000 free pre-rolled cones are available once the machine is paid in full and after any machine return window has expired. Free cone credits will be available at a rate of 10,000 cones per month over 5 months. Customer may choose any size or paper type of unbranded pre-rolled cones for the 50,000 free pre-rolled cones. Hemp wrap, designer tip, custom branded, or premium filter tip (wood, ceramic, or glass) do not qualify for this promotion, only standard unbranded pre-rolled cones. Shipping not included. Unbranded cones subject to availability.

Automated Pre-Roll Output/Hour

The first thing to consider is how many pre-rolls you need to produce per month. We offer automated pre-roll machines that range from 12 pre-rolls per minute to 30 pre-rolls per minute, even ultra-high output machines that can automatically produce 60 finished pre-rolls per minute. Of course you plan to grow, so you may want the largest automated pre-roll machine, but most companies prefer having multiple automated pre-roll machines, so they can produce different sizes or strains at the same time. Also, automated pre-roll machines are bound to go down for cleaning or repair, so with multiple machine, you ensure you can always meet demand. Set-up a call today to learn about all the options we offer, as well as all the considerations you should have in mind while shopping for an automated pre-roll machine.

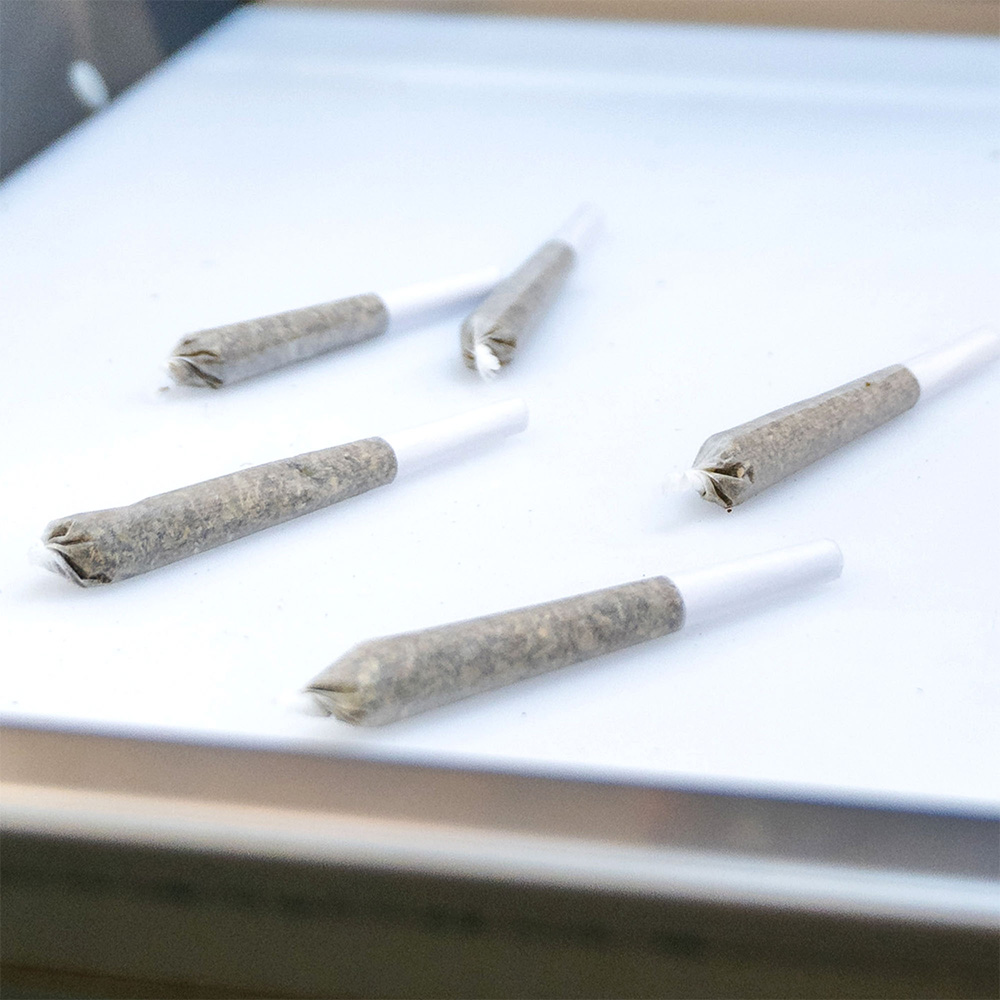

Pre-Roll Twist or Dutch Crown

Whether you want an automated pre-roll machine to produce a twisted top or a perfect dutch crown, we have automated machines that can do either one! Many consumers or brands are very specific on how they want their pre-rolls finished at the top, so we have automation solutions to help either route you want to go. Our automated pre-roll machines can also do a twist finish, cut the excess paper, and then stamp down the top of the pre-roll to create a flat top.

Upstream and Downstream Automation

Automated pre-roll machines don’t work without properly ground cannabis and the pre-roll manufacturing process doesn’t stop once the cone is filled and twisted. We offer pre-roll automation from the very first step of grinding and sifting, as well as secondary automation to automatically pack the finished pre-rolls as they come out of your automated pre-roll machine. From pre-roll multi-packs to labeling pre-roll tubes, our team of Pre-Roll Experts can help scale any part of your pre-roll production process. Best of all, you do not need to automate everything all at once! We can walk you through the most fiscally responsible steps to scale your pre-roll production process and add one piece of machinery at a time.