Automated Pre-Roll Machine Guide: Features, Types and Considerations

Posted by Custom Cones USA on Jun 1st 2023

In recent years, pre-rolls have exploded in popularity. They are now both the fastest growing product segment in the cannabis space as well as one of the largest segments in terms of sales in both Canada and the US. To keep up with the demand, producers needed machines that could manufacture pre-rolls a lot faster than they were able to manually with knockbox style pre-roll machines.

As demand for pre-rolls grew, so did the need for automated pre-roll machinery. These machines were created to help cannabis producers make pre-rolls in mass, but this doesn't mean they are going to be the right solution for you right away. There is a lot to consider before upgrading to automated pre-roll machinery. You have to take into consideration the types of pre-rolls you want to make, how well the machine works, the upfront cost of the machine, as well as your production needs.

In this article we will go over everything you need to know about the different types of automated pre-roll filling machinery. We’ll cover the ins-and-outs of the machines, when it makes sense to incorporate them into your pre-roll production (and when it doesn’t), and how you can get the most out of them after they have been installed. So let’s get into it!

What are Automated Pre-Roll Machines?

In short, automated pre-roll machines are machines that, once being set to specifications, operate automatically in the pre-roll making process with minimal human intervention. These machines still need to be monitored, maintained, cleaned, and supplied with raw materials, but they are extremely efficient at performing automated pre-roll production and even pre-roll packaging.

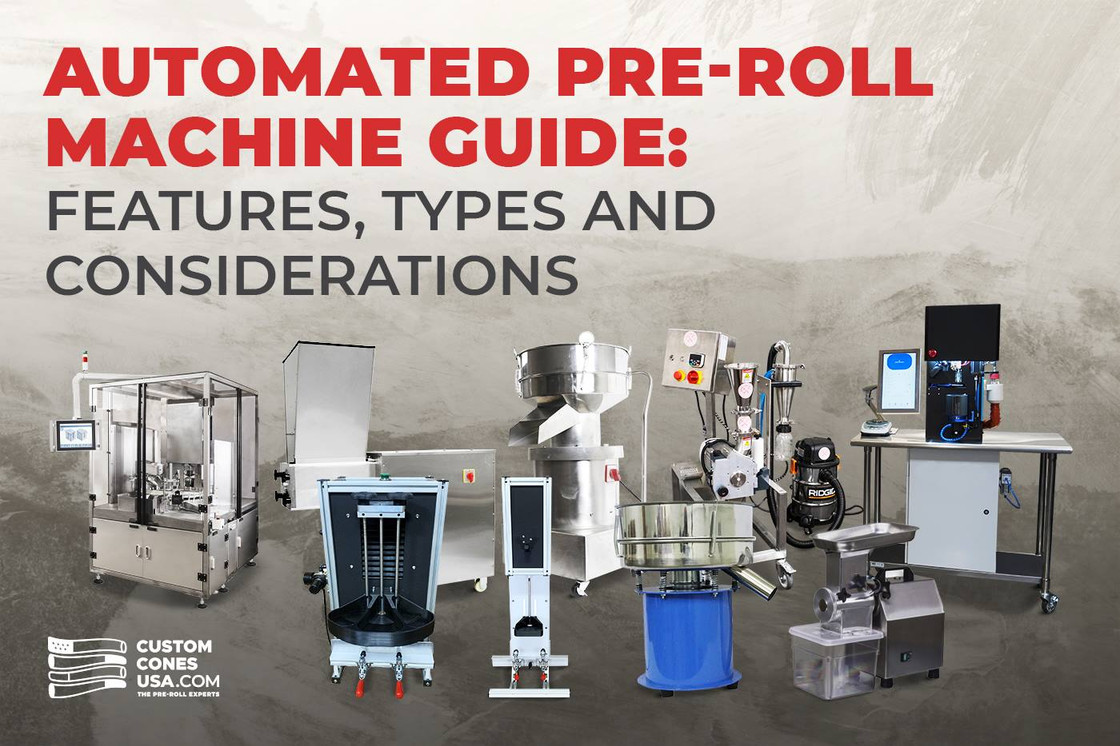

We offer automation for each step of the pre-roll making process. This includes automated machines that can grind, sift, fill, twist/fold, infuse, package, and label your pre-roll packaging. What’s also great about these automated machines is that they are modular in design. This means you don’t need to automate every step of your manufacturing process all at once. You can start with one machine and scale your production when it makes sense.

How Well Does Your Pre-Roll Machine Work?

There are a lot of factors that affect the overall pre-roll production you can achieve with automated pre-roll machines, but most of the responsibility falls on the person that is working with the machinery. Some machines, like grinders and sifters, do not require a lot of training and can be operated by the average employee. Other automated machines need to be operated by well-trained employees.

You also want to take into consideration the manufacturer of the machinery. This technology is still young, and experience goes a long way. It matters if your machine is a company's first attempt at making an automated pre-roll machine, or their 3rd or 5th iteration on a proven design. Knowing the machine you are buying is not the first generation means that this machine was out in the field, extensively tested by producers, and adjustments were made to improve the functionality based on their usage. There are many automated pre-roll machines out there, so it’s best to know the in’s and out’s of all the options and manufacturers in the market. That sounds like a lot of research! Thankfully our Pre-Roll Experts have been working with automated machinery since the beginning and can give you the advice you need to find the right machine.

Grinding Your Material for Automated Pre-Roll Machines

Next, you need to consider the impact of your starting material and how it is processed. Unlike a human assembler, automated cone filling machines will not adjust their process to accommodate variation, so consistency is the name of the game when it comes to using automated machinery. If the starting material is not consistent, it can cause issues for the machines. For example, automated pre-roll machines require that the cannabis material be more finely ground, drier, and have a consistent particle size to function properly.

You need the cannabis material to be able to flow through the machine effortlessly, so having material that is chunky, moist, or sticky will cause everything to slow down and/or not work properly. The temperature of the room you are operating the machine in even matters, because if you let it get too warm, the resin in the cannabis will become sticky and cause issues. This is why we always recommend you install and operate your automated pre-roll machine in a climate-controlled room. You not only want to keep the room cold, but also humidity controlled.

Lastly, you need to consider the quality of the cones you are using. In other words, you need to make sure you have cones that will work perfectly in the automation process. The machine isn’t going to realize if there are slight issues in the opening diameter or size of the cone and adjust to make it work. Some cones just aren’t going to be good enough to work with automated machinery, but don’t worry! Just like the machinery, we have done our research and guarantee the quality of all our pre rolled cones.

What Are the Automation Features of the Machines?

We offer automation solutions along every step of the pre-roll production process. Before you fill the cones, you can use the automated grinding and sifting machines to make sure that you get a particle size that will keep your machine working at optimal levels. The automated version of the Grindsizer 3 machine features a hopper, which can dispense predetermined weights of cannabis into the grinder and transfer that ground material directly into a sifter or your automated pre-roll filling machine. This helps reduce the number of human touch points, which both cuts down on labor costs, but also mitigates any chances of contamination. Once the flower is loaded into the automated grinder hopper, it is automatically ground at pre-determined intervals and then conveyed directly into the automated pre-roll machine with zero human interaction.

Each pre-roll filling machine will have a unique way of loading the pre-rolled cones. Some require the cones to be stacked by hand and others utilize trays that are designed to let the machine pick the cones. Once the cannabis and pre-rolled cones have been loaded into the machine, all that is left to do is double check to make sure the machine is calibrated correctly and turn it on.

Once in motion, the automated machines can do a number of functions. Features include automated cone de-nesting, cone re-forming station, damaged cone sensing system, customizable tamping station, precision twist station with top cutting, Dutch Crown station (only available on certain machines), load cells for individual pre-roll weighing, smart feedback loop for precision weight control, and even a pre-roll rejection system for non-compliant pre-rolls.

Automate Your Infused Pre-Roll Production

If you are making regular pre-rolls, you can move on to packaging and labeling, but, if you are making infused pre-rolls, there is an automated pre-roll infusion machine you should check out. Features include a cartridge that can hold 20 pre-rolls, a warmed concentrate reservoir to help keep the concentrate fluid, a specially designed injection needle, and a table control unit that lets you accurately determine how much concentrate goes into each pre-roll and where that concentrate is located. Automated infusion machines can infuse 800 cones per hour and use almost any kind of concentrate. Compared to painting the outside of the pre-rolls in oil and dusting in kief, this automated infused pre-roll machine injects the oil into the center of the pre-roll. By injecting in the center, you create a smoother burning and better tasting infused pre-roll. This is because compared to directly combusting the oil, as you would on with the outside infusion method, the ember of the pre-roll gently vaporizes the oil as it is burning the pre-roll.

Secondary Pre-Roll Packaging Automation

Finally, once your pre-rolls have been made, you can have secondary automation that can help you automatically package and label your pre-rolls. Whether you are looking to package single pre-rolls in tubes or multiple pre-rolls in packs, there is an automation option that can get the product in the packaging and labeled quickly. Some of these machines are so smart that they can even arrange pre-rolls within a multi-pack to your exact specifications, like zig-zagging up and down. Once your pre-rolls are in their branded package, all that is left to do is get them wrapped in an overwrapping machine or just label for final retail compliance.

How Much Do Automated Pre-Roll Filling Machines Cost?

There’s no way around it. A fully automated pre-roll machine is expensive. These machines typically cost between $200,000-$400,000+ and can sometimes be more! The difference in price will come down to the manufacturer of the machine (quality) and the features the machine offers. If you are just starting out, an automated pre-roll machine most likely will not be for you, but there are other machines you can investigate that can drastically increase your efficiency and productivity.

For about $4,000, you can get an Industrial Grinder and King Kone Filling Machine Starter Kit. With these two machines, a staff of two can produce around 2,000 pre-rolls a day. This can easily be scaled up to over 10,000 pre-rolls a day if you get multiple King Kones, additional filling trays, and a few extra employees on the job. All this to say, our team understands that automated machinery can be great for a company that is looking to scale up their production, but we also understand that they aren’t a one-size-fits-all solution to pre-roll manufacturing. Scaling up responsibly is vital for any business, and we can help you do just that!

When Does It Make Sense to Buy an Automated Machine?

Speaking of scaling up, there will come a time when it makes sense to invest in automation. As we mentioned before, the great thing about our automated machinery is that it is modular by design, so you can add machinery on an as-needed basis.

When it comes to automated pre-rolled filling machines, it starts to make financial sense to buy one when you need to produce more than 50,000 pre-rolls a month; however, there is more to think about than just the upfront cost. For the machines to run smoothly, you need to have good SOPs (Standard Operating Procedures) in place and low employee turnover. This means you are producing/sourcing cannabis that is consistent as well as processing it in a way that will maximize the efficiency of this type of machinery.

As we mentioned earlier, things like bud density, moisture content, water activity, and particle size all play a major part in an automated machine's ability to function. There are going to be some strains that just won’t work, and you will also have to make sure the cannabis material you can use is dried and ground to the appropriate levels. Having a Grindsizer 3 and a sifter is a great way to ensure that the bud is the perfect size for automated pre-roll production.

If you’re not quite ready to make the leap to 50,000 pre-rolls a month, you might be better served by a tabletop machine like the Fill N' Fold. This cone filling machine comes with a powerful vibrating motor and will make up to 121 tightly packed pre-rolls at a time. The Fill N’ Fold also comes with a tamping tool that makes folding easy and fast and produces a clean Dutch-crown like finish. As a more economical machine, it’s a great option for those looking to scale up their production but who might not be ready to embrace full-scale automation.

Lastly, it makes sense to start using this machinery when you need to work with the same cultivar and size of pre-rolls for extended periods of time. These machines are fast once they get going, but it takes some time to change the settings for a different pre-roll. Extended down time can eat into profits, so it’s ideal to run these machines when you only need to adjust for 1-2 different SKUs in a day. If you are trying to manufacture 3-5 different sizes of pre-rolls, with multiple strains per week, you are best using table top pre-roll machines, and we can still help you scale production and reduce labor costs.It is clear that there is a lot to think about when it comes to automated pre-roll machinery. As for the pros, these machines can reduce labor costs, lower chances of contamination by eliminating human interaction with the product, increase the consistency of each pre-roll (weight and look), and drastically increase your daily output per employee, but it’s not all positives.

When you decide on using automated machinery, you are also deciding to use cannabis material that is drier and more finely ground than you would typically like and is possible to pack in table top pre-roll filling machines. You are also signing up for longer changeover and cleaning times, so doing multiple SKUs a day becomes more time consuming. These machines are expensive to fix, not to mention the missed production time if it is your only machine and it is down. Many of these machines also require highly trained operators that are technically minded. This isn’t a position that you want to see high turnover in. It’s a dedicated position, and, if a company tells you that a single person can run multiple machines, you should be skeptical.

There is a lot to consider before upgrading to automated pre-roll machinery. You have to take into consideration the types of pre-rolls you want to make, how well the machine works, the upfront cost of the machine, as well as your production needs.