Fill N' Fold Deep Dive

Posted by Custom Cones USA on Dec 3rd 2024

As the pre-roll market continues to expand and more and more consumers turn to pre-rolls for their ease, convenience and innovation, any cannabis company that wants to stay competitive is going to need to be able to produce high-quality pre-rolls to meet rising consumer demand.

When it comes to cone-filling machines, the Fill N’ Fold might just be the easiest and fastest way to turn out large numbers of top quality pre-rolls at scale, thanks to its unique folding and tamping tool that cuts down on the amount of time necessary to close each individual pre-roll.

With an affordable price and small footprint, the Fill N’ Fold is a great cone-filling machine for any size company, from those just getting started to established brands looking to speed up production or add another pre-roll line.

But what makes it such a great investment? Let’s get into it.

Speed

The main reason to use the Fill N’ Fold instead of any other cone-filling machine is simple: the special closing/tamping tool drastically speeds up the production process.

According to our surveys of pre-roll manufacturers, the No. 1 pain point and slow down in the production process is not grinding or filling, but closing the already-filled pre-rolls. What sets apart the Fill N’ Fold is that it directly addresses this point.

Each Fill N’ Fold comes with a special tamping/folding tool that allows a user to fold over and close the tops of 11 pre-rolled cones at a single turn. The easy-to-use tool is a simple way to create a Dutch crown-style finish, without the complications of working each pre-roll cone individually.

The Holes Fallacy

We put the Fill N’ Fold to the test as part of our "Battle of the Pre-Roll Machines" to figure out which cone packing machine produced the largest number of cones in an hour. Despite having fewer slots for pre-rolled cones than some of its competitors, the Fill N’ Fold’s tamping and folding tool allowed it to easily outperform the other machine in both our single-operator and double-operator tests, disproving what we call the "Holes Fallacy."

Put simply, the Holes Fallacy is the notion that more cones per filling cycle means more pre-rolls being produced per hour of operation.

The truth is that there are a variety of factors that go into throughput. And while it begins with the number of pre-rolled cones or pre roll tubes any given machine can produce during a single packing cycle, it also includes employee experience, run time and, most importantly, how you close and finish your pre-rolls.

Which is where the Fill N’ Fold excels. The Fill N’ Fold can fill 121 cones in a single cycle, but its speedy packer and tamping and folding tool allows it to easily outpace other machines when it comes to creating completed pre-rolls.

In the single operator test:

- The Fill N' Fold produced an average of 837 pre-rolls with a Dutch crown finish per hour

- The King Kone produced 585 pre-rolls that were twisted closed per hour

- The Knockbox produced 529 pre-rolls with a twist close per hour

When we added a second operator and spare parts:

- The Fill N' Fold's output increased to 1,361 pre-rolls per hour with a Dutch crown finish

- The King Kone followed with 1170 completed pre-rolls with a twist close

- The Knockbox produced 1000 cones per hour, also with a twist close

So, as you can see, the Holes Fallacy is, in fact, a Fallacy.

Ease of Use

The Fill N’ Fold uses a powerful, vibrating motor to pack its cones. Its simple, mobile design consists of only a few parts: the packer and vibrating base, the color-coded work trays and volumetric metering trays and the folding and tamping tool. Simply plug in the base and it is ready to go.

Pre-roll techs simply place the work tray of cones over the packer and vibrating base, fill the enclosed, color-coded volumetric metering tray with flower, place it over the work tray, slide out the metal sheet to release the flower and turn on the machine. When done, the folding and tamping tool is used to close the pre-rolls, which can just be popped.

Employees can be trained to use the Fill N’ Fold in minutes, reducing the time to onboard while ensuring continuous production, even if employees are home sick or there is turnover among your pre-roll crew.

Durability

Made from high density plastics, this high quality, well-built joint filling machine is ready for the toughest work environments. All the Fill N’ Fold’s parts are made from machine-grade materials and are handmade by engineers using a CNC milling machine and other power tools.

With simple maintenance, the Fill N’ Fold is an affordable workhorse of a cone-filling machine that will become a cornerstone of your production process and outlast nearly every other machine on the market.

What comes with the Fill N’ Fold?

Each Fill N’ Fold machine comes with:

- a packing base (the motor);

- One (1) color-coded work tray designed to hold a single size of pre rolled cone;

- a volumetric metering tray of the same color and size as the work tray;

- Two (2) metering adjustment shims;

- a bucket with lid;

- a tube brush;

- a catch tray;

- a scraper; and

- One (1) of the special folding/tamping tools.

Customers looking to pack multiple sizes of pre-rolled cones will need to purchase additional work trays and metering trays, though the packing base works with all sizes of pre-rolled cone. We offer both single and double packages to help get you started.

Sizes of work and metering trays include 70mm, 84mm, 98mm and 109mm.

How to Put Together the Fill N’ Fold Cone-Filling Machine

The Fill N’ Fold is a remarkably simple and easy-to-use cone-filling machine. It comes basically ready-to-use right out of the box.

Simply slide the work tray over the motor and packing base, add a volumetric metering tray on top of that and you are ready to begin filling cones.

How To Use the Fill N’ Fold Cone-Filling Machine

The Fill N’ Fold is easy to learn to use and to master. Begin by plugging in the motor, then set it aside for a moment and follow these step-by-step instructions:

- Fill the slots in your work tray with pre rolled cones that match its size. It’s easiest to do this when it is not over the base, we recommend using the weight from a cone stack to help drive the cones deep into the slots. Once they are loaded, give the tray a quick bump or two on your table to help drive all of the cones all the way in. They do not need to be flush but should not be sticking out more than about 2 millimeters.

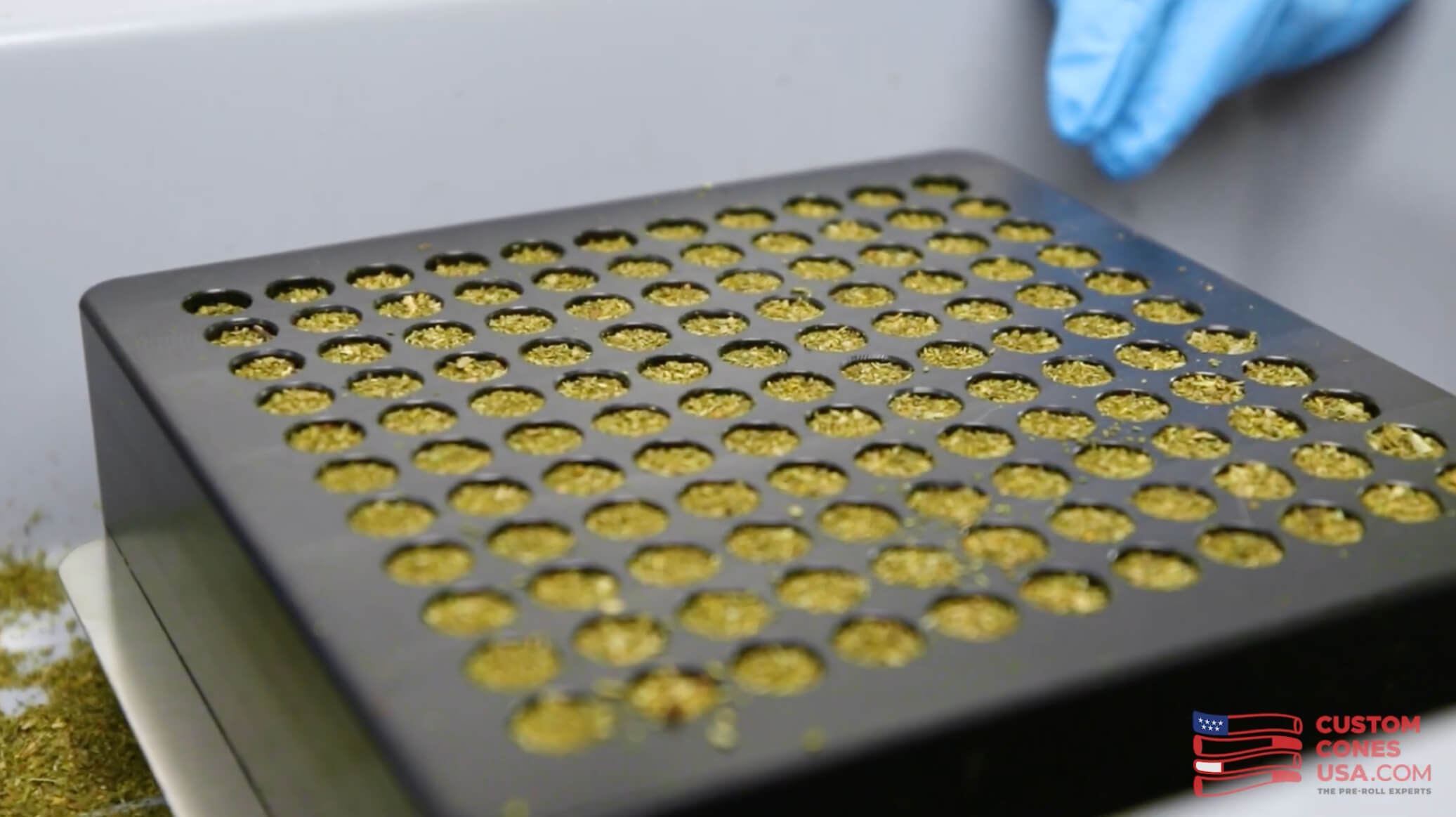

- Once the cones are loaded into the base, turn your attention to the corresponding volumetric metering tray. Place it over a bin and simply pour your ground material over the top, spreading it across until each slot is filled evenly.

- If the volumetric metering is off a little, use one of the extenders or shims to add a little extra flower.

- Once the metering tray is loaded, place the tray on top of the work tray and pull the metal sheet out so the flower falls through to the cones below. You may need to tap the top of the metering tray to make sure all of the flower falls through.

- Once the flower is loaded into the cones, place the work tray on top of the motorized base and use the dial to control the speed of the motor. We suggest using the “low” setting and starting slowly before gently increasing it to between 60 and 70%. Anything above that may bounce flower out of your cones or even your cones out of the machine.

- Let the machine run for one to two minutes until the flower is packed to your preferred density.

- When you’ve finished packing, remove the work tray from the base and grab the tamping/folding tool. First, use the row of flat black teeth (they look like flathead screwdrivers), called the crimpler. The goal here is to crimp the paper inward. Do not worry about folding the cone like a present, just crimp the excess paper inwards, so once you move to the next step, you are able to fold down the rest of the paper.

- To fold in the remaining paper at the tops of the cones, use the black tamping section of the folding tool, which both tamps the tops of the cones and presses down the remaining paper to create a flat, Dutch crown style top.

- Now just rotate your packing tool to the ejecting section, which is the longest part of the folding tool. Push firmly. This motion will finalize the fold at the top and eject the line of pre-rolls out of the machine onto your table or into a bucket. Using a rocking motion helps spread out the force needed to eject all the cones and puts less strain on the user, making this part easier.

The Fill N’ Fold Starter Kit

For companies just getting started in the pre-roll game, we offer a Fill N’ Fold starter kit that includes everything you need to go from flower to perfectly packed pre rolls.

Along with your choice of Fill N’ Fold cone-packing machine, our Fill N’ Fold Starter Kit comes with the Industrial Cannabis Grinder, built specifically for cannabis, an optional sifter and $150 in store credit, giving you a head start on buying the pre-rolled cones that match your Fill N’ Fold’s work tray size.

Unlike whip or shredder style grinders, the industrial cannabis grinder uses a low rpm, high torque motor that reduces heat to preserve trichomes and cannabinoids, while its three screen sizes ensure the consistent particle size you need for your pre-roll brand. Able to grind up to 1 pound per minute, the stainless-steel grinder is as easy to clean as it is to use, keeping your pre-roll production flowing smoothly.

Metering Trays

Making sure your material is evenly distributed among your pre-rolls is important for consistency and compliance, as well as keeping costs in line. Uneven material distribution may cause weight variances and create extra work fixing those variances in order to make your pre-rolls the correct weight to remain compliant.

Metering trays can not only help solve both problems, they also help speed up the production process by making it easier to fill the proper amount of flower prior to beginning the packing process.

The Fill N’ Fold uses volumetric metering trays color-coded to match the proper size work trays as a way to help create consistent pre-rolls. The key word here is "volume" - the metering tray is not actually weighing the flower, but since each hole is the same volume, in theory, the same amount of flower should be getting dropped into each cone.

For example, each slot in a half-gram, or 84mm cone, metering tray has a volume of about 3 cubic centimeters, which equates to about a half-gram of flower, give or take, with the exact weight always coming down to differences in the flower itself. For example, some strains are naturally denser than others, so a denser strain will weigh more in the same volume as a lighter, fluffier strain.

The metering trays are filled and then placed on top of the work trays. When the metal sheet is removed, the flower falls into the cones and then the Fill N’ Fold’s vibrating motor works to pack the cones to the perfect smoking density.

Because each Fill N’ Fold work tray only fills a single size cone, Fill N’ Fold metering trays are color-coded for ease of use.

To Sift or Not to Sift

The Fill N’ Fold Starter Kit comes with an optional sifter. Though sifting is optional, it is an often overlooked, but important step that can not only help ensure particle size consistency and help remove stems and other jagged bits from potentially tearing your pre-rolled cones, it can also help increase your pre-roll output.

In fact, we ran an experiment to demonstrate how necessary sifting actually is.

What we discovered is that:

- Weight variances occurred 65% more often in un-sifted material than in sifted material.

- The number of pre-rolls that ended up with holes due to stems occurred 488% more often in un-sifted material than in sifted material.

- The number of pre-rolls with a dissatisfactory pack was 194% higher in the un-sifted materials.

We ran the experiment using a different cone packing machine, but the results speak for themselves. The sifted material created a more even pack and a more even distribution of flower amongst the pre-rolls. In a run of 169 pre-rolls, we got 27 more pre-rolls when using sifted material rather than un-sifted, an increase of 16%. Translated to the Fill N’ Fold’s 121-cone production cycle, that’s an additional 19 usable pre-rolls per run.

The value is clear; sifting your flower saves money, creates a higher-quality product, and produces a higher output of product.

Other Pre-Roll Filling Machines

If the Fill N’ Fold is not right for your company, consider the King Kone cone-filling machine. Sturdy and versatile, the King Kone has a unique bounce motor that can fill up to 169 pre-rolled cones at one time. It can be used with any size pre-rolled cone and even has a tube conversion kit for producers looking to switch things up on their pre-roll line.

The two machines have different strengths and weaknesses, however.

For example, if you are only making one or two basic-sized pre-rolls, the Fill N’ Fold is the way to go because of its ease of use and the shortened production time the tamping/folding tool provides. With a simple training session, the Fill N’ Fold has the ability to turn out thousands of high-quality pre-rolls in less time than any other machine.

However, if your company plans on creating multiple pre rolled cone sizes and/or plans to use pre-rolled tubes as part of its line, the King Kone might be a better choice, particularly if you are just starting out. Right out of the box, the King Kone can produce 84mm, 98mm and 109mm pre-rolls, as well as 90mm pre rolled cones with glass or ceramic tips. And with a simple attachment kit, it can produce 9mm and 11mm tubes as well.

Final Thoughts on the Fill N’ Fold

The Fill N’ Fold cone-filling machine is the fastest start-to-finish pre-roll machine in the industry. No matter what size pre-rolls you are producing, the Fill N’ Fold’s easy-to-use metering and work trays will create consistent, high-quality smokes every time. Add in a grinder and a sifter and it’s the perfect bundle for companies looking to launch or expand their pre-roll lines.

Contact the Pre-Roll Experts today to see which Fill N’ Fold is right for your needs!

As the pre-roll market continues to expand and more and more consumers turn to pre-rolls for their ease, convenience and innovation, any cannabis company that wants to stay competitive is going to need to be able to produce high-quality pre-rolls to meet rising consumer demand.