Pre-Roll Master Class: Part IV – Pre-Roll Infusion Methods and Automation

Posted by Custom Cones USA on Jun 10th 2025

Welcome back to Part IV of the Custom Cones USA Pre-Roll Expert Master Class where we are covering the fundamentals, as well as tips and tricks, of creating high-quality pre-rolls at scale.

We’ve spent years studying what goes into making perfect pre-rolls and our mission is to revolutionize and enhance pre-roll products by setting a benchmark for excellence and innovation in the industry by sharing that knowledge.

In Part I, we covered Paper Science 101, looking at the basics and science of what goes into making the rolling papers that make pre-rolled cones.

In Part II, we covered the Importance of Proper Grinding and Sifting.

In Part III, we looked at some of the Best Practices for Pre-Roll manufacturing.

Today we are taking a deeper look at the top-selling segment of the pre-roll category, the infused pre-roll.

Once you’ve mastered standard pre-rolls and it’s time to diversify your product line, the next challenge is making infused pre-rolls.

What is an Infused Pre-Roll?

An infused pre-roll is one that has been enhanced with cannabis concentrates to increase its potency and/or flavor. These concentrates can be applied in two main ways: externally, where the concentrate is applied to the outside of the joint, or internally, where it's mixed with the flower or placed inside the joint.

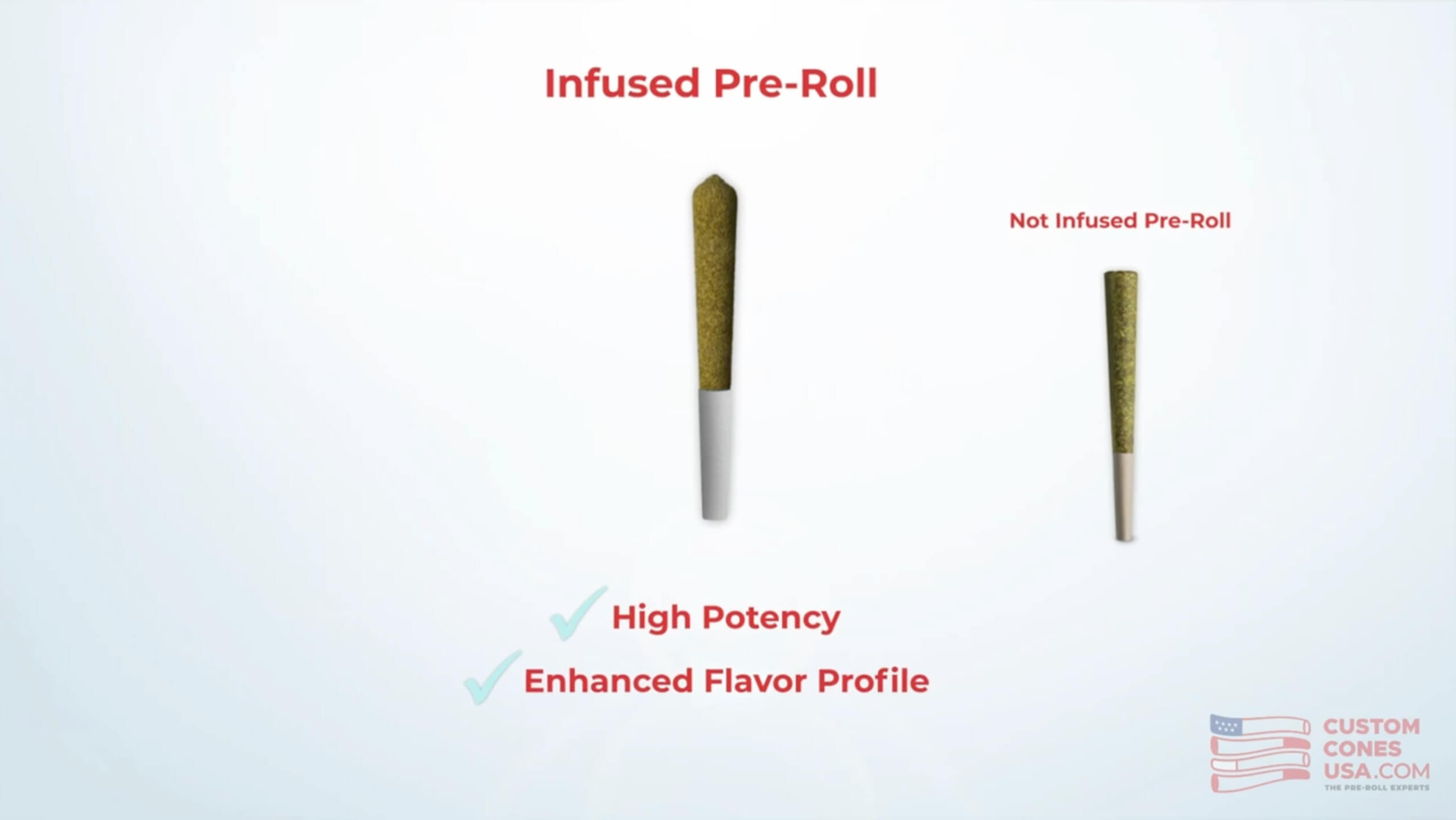

The world of infused pre-rolls offers a wide variety of options. Manufacturers use different types of concentrates like kief, distillate, bubble hash, live resin, BHO (Butane Hash Oil), and hash rosin to create unique products. This variety is one of the reasons why infused pre-rolls have become so popular among cannabis consumers. They offer higher potency and enhanced flavor profiles, allowing users to customize their experience.

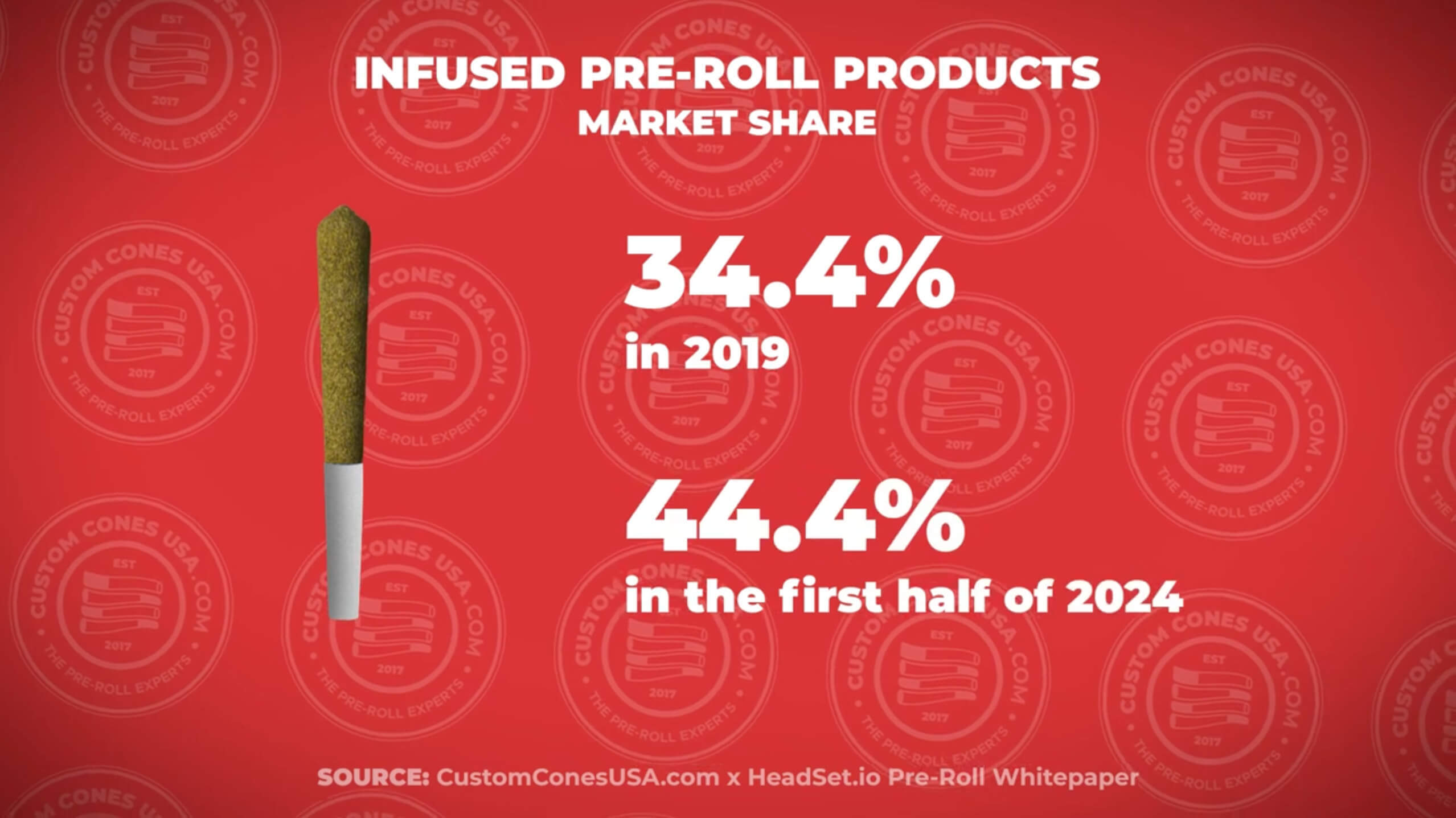

And customers are responding. In 2023, the infused segment became the top-selling segment in the pre-roll category. According to data from cannabis analytics firm Headset, the Connoisseur/Infused segment dominated the charts in 2023 and the first half of 2024, accounting for more than $1.75 billion in sales – edging out Hybrid - Single Strain and its $1.64 billion in sales for that time, due in part to the higher price point created by added concentrate.

Perhaps even more impressive is the increase in market share for infused pre roll products, jumping from an average of 34.4% in 2019 to 44.4% in the first half of 2024. So you can see why more and more manufacturers are jumping into the infused segment.

As you can see, every pre-roll brand needs to seriously consider adding infused options to their line as a way to keep up with changing consumer demands.

How to Infuse Pre-Rolls

There are two main methods for infusing pre-rolls: internally and externally.

Externally Infused Pre-Rolls

The primary external method is the paint and kief method. It is relatively simple but requires attention to detail to create a high-quality product.

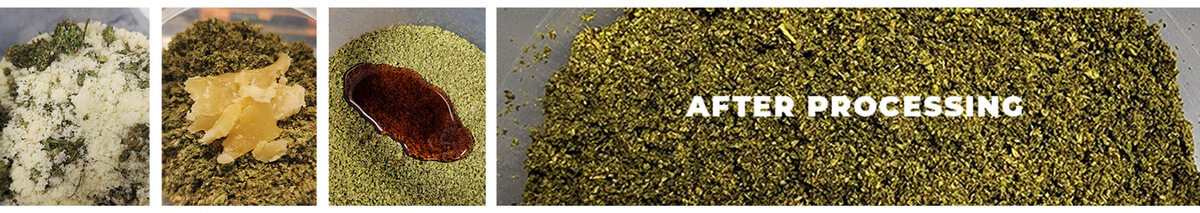

The process begins with preparing the concentrate. Distillate is a common choice due to its high potency and ease-of-use. First, producers heat the concentrate to reduce its viscosity, making it easier to work with. A vacuum oven is ideal for this step, as it allows for precise temperature control. It's crucial not to overheat the concentrate, as this can degrade the cannabinoids and terpenes.

Once the concentrate is ready, a food-grade brush is used to “paint” the concentrate onto the outside of the pre-roll. After applying the concentrate, the pre-roll is rolled in kief. Kief is the golden dust made of trichomes – or the part of the flower that contains the cannabinoids and terpenes – that have been knocked off during the grinding or sifting process.

Many sifters – as well as many small, personal use grinders – use a fine screen to further sift and collect kief so it is not wasted. In this case, the kief coating not only adds potency but also gives the pre-roll an attractive, frosted appearance.

While this hand-crafting method allows for a visually appealing and customizable product that looks great in a glass or clear plastic tube, it does have its drawbacks. The process is time-consuming and can lead to inconsistencies in application.

Additionally, having the concentrate on the outside of the joint can result in a harsher burn and potential loss of potency through what is called “side smoke,” or smoke that burns off the side of the pre-roll instead of being inhaled.

Just a note though: We have seen some producers use ground cannabis to dust the outside of their pre-rolls and call them infused. But not only does it not have the same kick as kief, ground cannabis has a green hue instead of the golden color of kief. Customers can quite easily tell the difference and won’t come back if they feel they’ve been had, so always use actual kief.

Internally Infused Pre-Rolls

Internal infusion involves either mixing the concentrate with the flower ahead of time or placing a snake-like tube of a thicker concentrate, usually resin, hash rosin, butane hash oil or another thick, sticky concentrate that can be molded.

These tubes of concentrate can either be molded by hand and placed inside the cones or injected using a machine. When smoked, the burning flower vaporizes the concentrate leaving the popular doughnut or “hash hole” look.

Automated Pre-Roll Infusion

As demand for infused pre-rolls grows, manufacturers are turning to automation to increase production and ensure consistency. Let's look at three key machines that are changing the game.

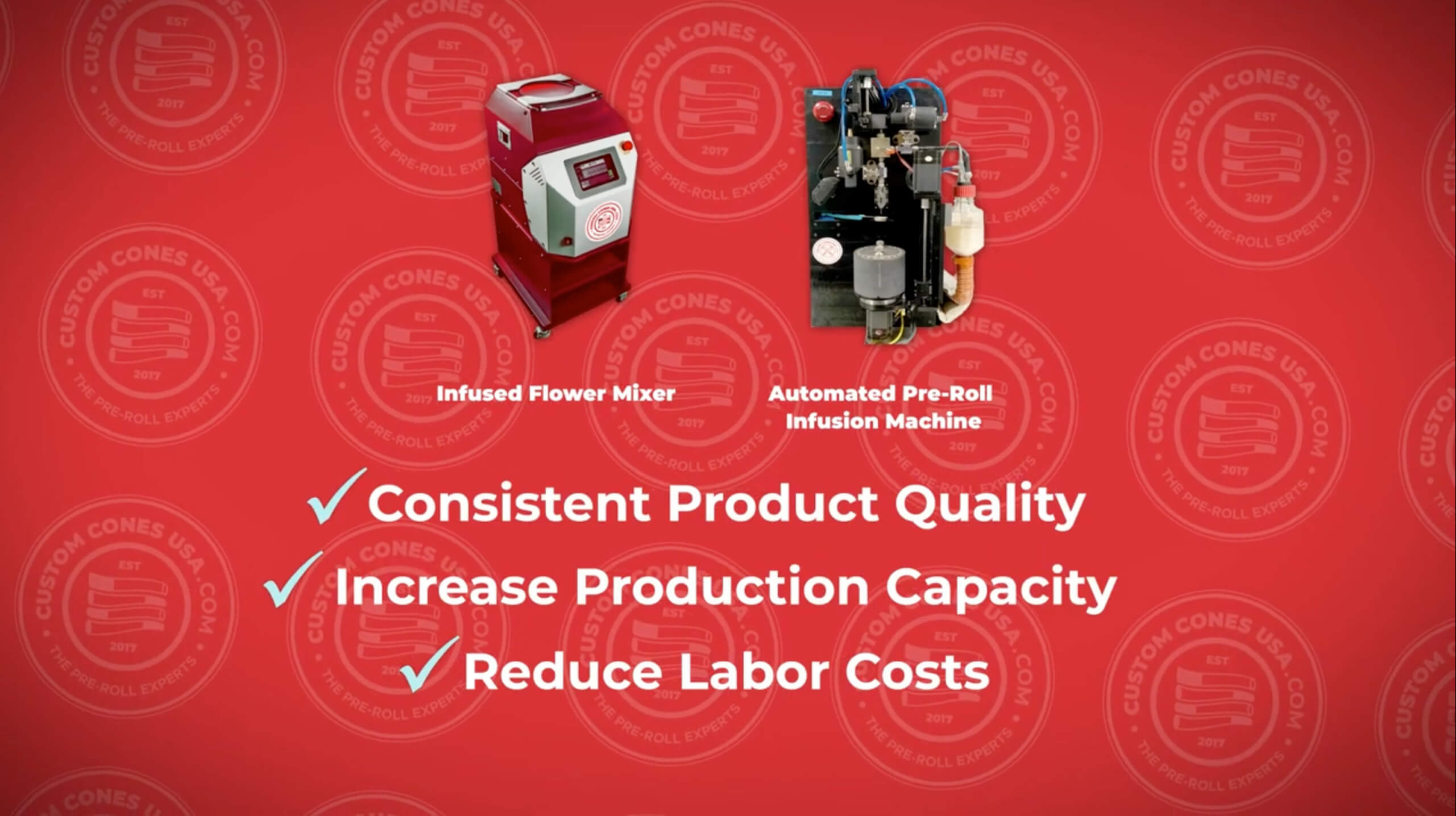

Infused Flower Mixer

The first is the Infused Flower Mixer. This innovative machine streamlines the internal infusion process. It uses a dual centrifugal action to thoroughly mix flower with any type of concentrate in just minutes. It will perfectly homogenize the flower with whatever concentrate you choose, and does so without the increased heat of a vacuum oven, leaving your trichomes in better shape as well.

The beauty of the Infused Flower Mixer machine is its simplicity - just add your flower and concentrate, and the machine does the rest, ensuring a consistent mix every time. This not only saves time but also reduces the number of steps in the production process.

But just a note: Infusing your flower may throw off volumetric measurements as infused flower weighs more but takes up about the same amount of space. It is also stickier so your machines will need more rigorous cleaning following a run of infused flower.

Automated Pre-Roll Infusion Machine

For those looking to take pre-roll infusion to the next level, there's the Automated Pre-Roll Infusion Machine.

This sophisticated device offers precise control over the infusion process and can handle up to 20 pre-rolls at once. It features a touchscreen interface where operators can set exact parameters for the infusion, including the amount of concentrate, the infusion location within the pre-roll, and the length of the infusion.

The machine works by injecting concentrate through a medical-grade needle into the center of each pre-roll. This internal infusion method helps ensure a more even burn and potentially better preservation of terpenes compared to external application methods.

Both of these machines offer significant benefits for large-scale producers. They ensure consistent product quality, increase production capacity, and reduce labor costs. Additionally, they often provide detailed production data, allowing manufacturers to continually optimize their processes.

Automated Kief-Coating Machine

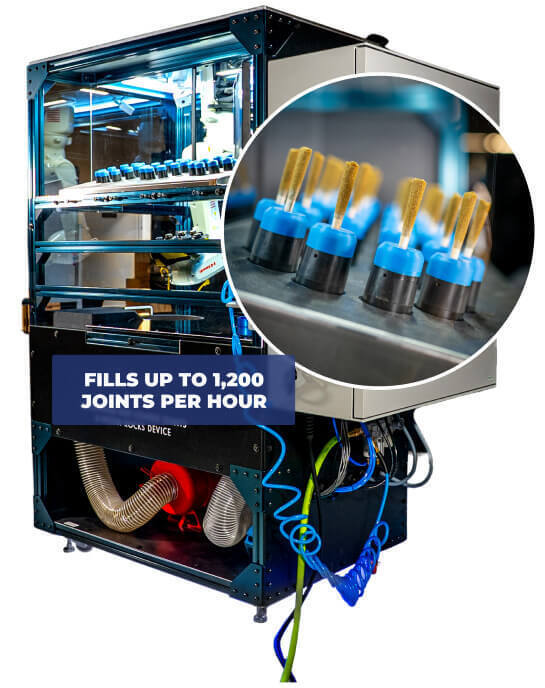

For producers looking to externally infuse pre-rolls at scale, the Automated Kief-Coating Machine provides consistency and speed.

The Automated Kief Coating Machine is a specially designed machine that can produce 10 kief-coated pre-rolls of any size in just 30 seconds, or up to 1,200 per hour with just a single operator. Its touchscreen interface allows users to create and save coating profiles, make adjustments in real time, and track production analytics for important insights.

This machine is compatible with pre-rolled cones, pre-rolled tubes and pre-rolled blunts of ANY size, and can coat pre-rolls with a wide range of extracts and adhesives.

It works with distillate, live resin, rosin or even Arabic gum and other water-based solutions. For the external coating, users can apply Kief, Bubble Hash, crushed THCa Diamonds or even ground/powdered cannabis.

But whether you are using automated machines or not, increased consumer interest and sales make infused pre-rolls a must-have addition to any modern pre-roll line.

And finally, in Part V, we’ll get into Pre-Roll Packaging and Testing Considerations.

Welcome back to Part IV of the Custom Cones USA Pre-Roll Expert Master Class where we are covering the fundamentals, as well as tips and tricks, of creating high-quality pre-rolls at scale.