2025 Pre-Roll Cone Filling Machine Report by Custom Cones USA

Posted by Custom Cones USA on Oct 25th 2025

When it comes to your pre-roll production line, perhaps the most important decision you have to make is your cone filling machine.

The right machine can speed up your process and keep things moving smoothly. But the wrong one might cost you too much, not be able to handle all of the pre-roll products you want to create or be unable to scale up to meet demand.

With various sizes, features and even different types of filling mechanisms, the world of pre-rolled cone-filling machines can seem daunting to the inexperienced. It can be hard to wrap one’s head around just how many ways there are to fill a cone.

Whether you choose a vibrating machine, a bounce machine, a fully automated roller or even one that your employees have to shake by hand, it’s important to understand the different options and accessories that come with your machine, the machine’s capabilities and costs surrounding them.

So which pre-roll machine is right for you? The Pre-Roll Experts are here to help.

But before we get into the specifics of each of the major cone filling machines, let’s get a few basic questions out of the way.

What Makes a Good Cone Filling Machine?

Put simply, a cone filling machine fills pre-rolled cones. But the best cone filling machines go beyond just meeting your most basic of needs.

Perhaps the biggest mistake new producers make is simply buying a cone filling machine based on the number of pre-rolls it can fill in a single cycle, thinking that will produce the most pre-rolls and therefore must be the best machine.

We call this the “Holes Fallacy.”

The truth is that there are a variety of factors that go into throughput. And while it begins with the number of pre-rolled cones or pre-roll tubes any given machine can produce during a single packing cycle, it also includes employee experience, run time and, most importantly, how you close and finish your pre-rolls.

In fact, that last step – closing the pre-roll – is what we hear all the time as the biggest pain point and time-consuming part of pre-roll production. And you are only going to be able to produce pre-rolls as quickly as your slowest station on your production line.

Battle of the Pre-Roll Machines

Custom Cones USA ran its own experiment using three different cone-filling machines to see which produced the most completed pre-rolls the fastest.

The Fill N’ Fold cone filling machine uses vibration to fill up to 121 cones per cycle. It comes with a special tamping tool designed to help tamp down the flower and then fold down the tops of all your filled cones at the same time, creating a "Dutch crown" style finish.

The King Kone filling machine is a versatile cone filling machine with the ability to pack up to 169 pre-rolled cones in each cycle. It comes with a tamping tool that was used as part of the experiment. Cones must be closed by hand (we used a twist).

The Knockbox 100 uses vibration to fill up to 100 pre-rolled cones per cycle. It is compatible with multiple different cone sizes. A volumetric “filling kit” can be purchased, though it is not size-specific, so any flower that does not fit in the cones you are filling falls around the machine during use. Cones were closed by hand with a twist.

In the single operator test, the Fill N' Fold produced an average of 837 pre-rolls with a Dutch crown finish per hour, the King Kone produced 585 pre-rolls that were twisted closed per hour, and the Knockbox produced 529 pre-rolls with a twist close per hour.

When we added a second operator and spare parts, the Fill N' Fold's output increased to 1,361 pre-rolls per hour with a Dutch crown finish. The King Kone followed with 1170 completed pre-rolls and the Knockbox produced 1000 cones per hour, both with a twisted finish.

So as we see, the machine with the most holes – the King Kone – did not win. In fact, it got smoked by the smaller Fill N’ Fold and its tamping and folding tool, producing a similar number of completed cones to the Knockbox, disproving once and for all the “holes fallacy” that more cones per cycle results in more completed pre-rolls.

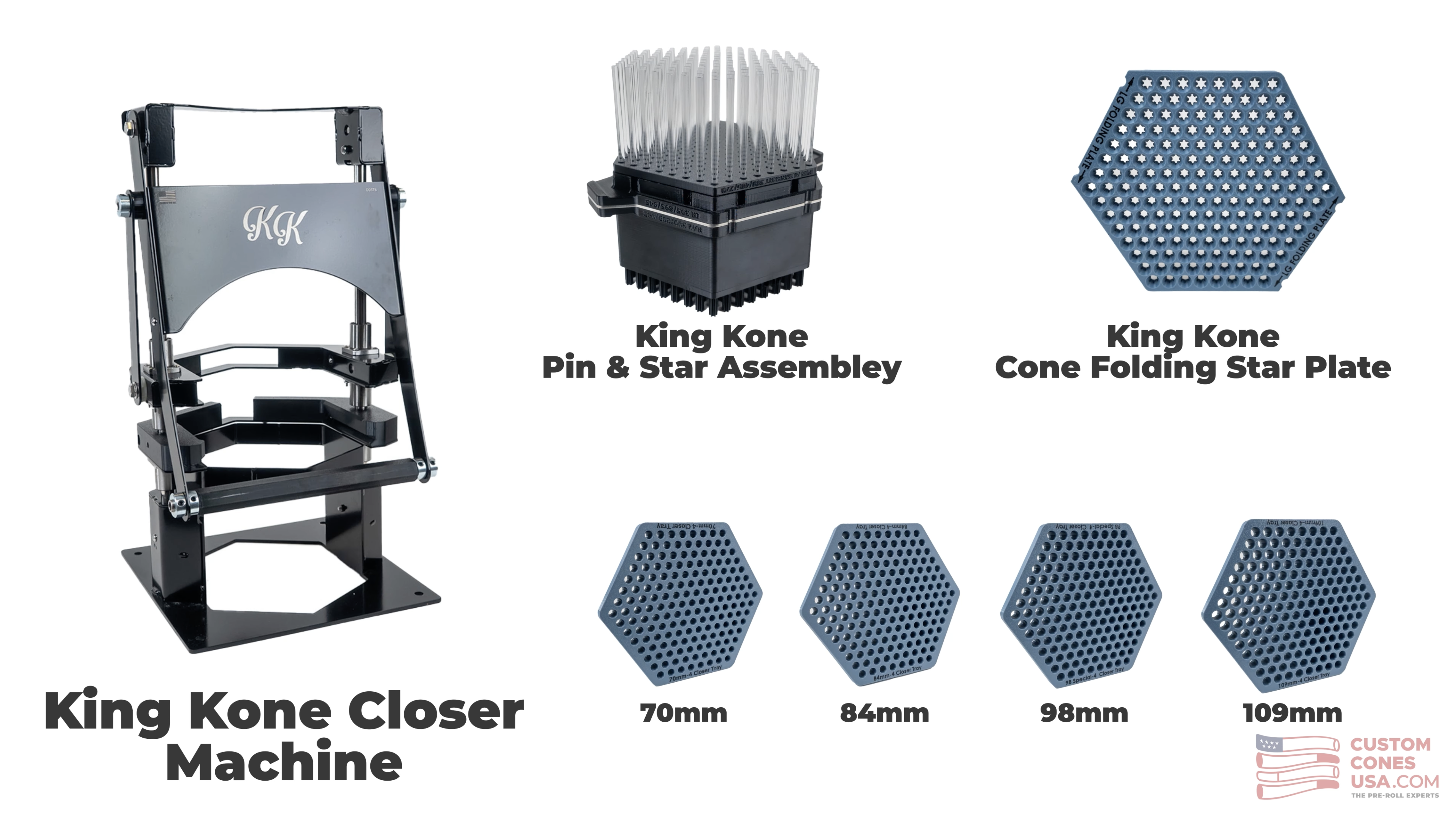

Another important factor in efficient production is staying up to date on advancements in machines and their accessories. For example, King Kone has added a Closer that greatly reduces the time required to finish pre-rolls at scale, similar in concept to the Fill N’ Fold tamping tool.

Bottom line: you can ignore the Holes Fallacy; more holes do not always mean more pre rolls. But there are a few things you should look for:

Speed and Efficiency

The best cone filling machines work quickly, filling dozens of pre-rolled cones at one time and providing an easy and speedy way to close them without slowing down the process too much.

Versatility

Pre-rolls come in various sizes and shapes, and the best pre-roll filling machines can handle multiple sizes, as well as multiple shapes, including cones and tubes.

Maintenance

Filling cones is messy, sticky work and all machines need to be cleaned. Top pre-roll filling machines are easy to maintain and easy to clean so your production is not slowed down.

Cost

Different sized businesses need different sized pre-roll machines, and the best pre-roll machine for your business is one that gets the job done without breaking the bank.

What Kinds of Features Do Cone Filling Machines Have?

Not every cone filling machine has the same features, so it’s important to focus on what matters most to you and your business. Key features include:

Adjustable Vibration/Bounce Rate

Not all cannabis packs the same, so being able to adjust the speed of your pre-roll machine’s vibration or bounce is key to dialing in the right processes to create high-quality pre-rolls.

Conversion Kits

Some pre-rolled cone filling machines have a tube-filling option that, when purchased and used, allow producers to expand their pre-roll lines beyond traditional cones and into pre-rolled tubes and pre-rolled blunts.

Metering Trays

Adding the correct amount of flower into any given cone can be a headache for workers and a slow-down in your production line. A metering tray allows for the same amount of flower to be dropped into every cone slot at the same time, speeding production.

Metering trays are usually volumetric in nature and are sized to correspond with traditional pre-rolled cones sizes. For example, metering trays designed for 109mm cones usually hold about 1 gram of flower per slot.

A Cone Closing Method

One key feature that speeds the entire pre-roll production process is a closing method, whether automated, by tool or a separate mechanism. No matter how many cones your pre-roll filling machine can pack at a single time, they all have to be closed and if you are doing that by hand, the time for each production cycle could more than double, depending on your closing method.

Cone Slots

One of the primary concerns any pre-roll maker should have when choosing a machine is the number of pre-rolls it can fill in a single cycle or time span. While not the be-all, end-all when it comes to speed, the number of cones a pre-roll filling machine can hold is a key factor. However, as we noted above, don’t fall for the Holes Fallacy that the machine that holds the most cones produces the most pre-rolls per hour...

What are the Different Types of Cone Filling Machine?

There are multiple types of cone filling machine, for every size budget and production facility, ranging from simple, hand-held devices to large, automated machines that produce thousands of pre-rolls per hour.

Non-Electronic Cone Filling Machines

The simplest and smallest machines are non-electric tabletop pre-roll cone filling machines that users simply fill with a pre-measured amount of flower and then manually bump the box against a table to pack the flower into the cones. They have a low start-up cost and ease of us, but they are usually smaller and do not have the speed or versatility of electronic models.

Electronic Tabletop Cone Filling Machines

These are the most common cone filling machines in the industry, capable of producing more than 100 pre-rolls in each production cycle through the use an electronic motor to pack a pre-measured amount of flower into the cones, all while having a small footprint on a tabletop or work bench.

Many cone filling machines use a vibrating motor to get this done, while others use a bounce motor to distribute and pack the flower through each cone, but either way, these machines are usually small enough to be carried and set up by a single worker.

Large Electronic Cone Filling Machines

As the name implies, these are larger cone filling machines. Larger and less likely to be moved, these machines often fill more cones at one time using motors that do not simply bounce or vibrate.

They usually take more training and come with higher price tags, but usually produce more pre-rolls per hour with less manual work than the smaller, tabletop models, making them attractive to larger pre-roll businesses.

Automated Cone Filling Machines

The largest and most expensive in the category, automated cone filling machines are designed for the largest producers, such as those that produce at least 50,000 pre-rolls per month.

Automated pre-roll machines can take boxes of cones and ground cannabis and automatically fill, weigh, pack, tamp, twist, cut off any excess paper and even weigh the final joint, delivering a level of consistency and automation unmatched by traditional pre-roll manufacturing methods.

Automated pre-roll machines can typically produce between 1,000 and 2,000 pre-rolls per hour depending on the size and level of automation, with some able to run autonomously for hours with minimal human supervision.

How Do I Choose a Pre-Roll Cone Filling Machine?

There’s no one correct choice of cone filling machine for your business, though there may be wrong ones.

Choosing the right cone filling machine means picking the throughput, features and costs that are right for your company and the size of its pre-roll production line for now and in the future.

Pick a machine that is scalable to your needs, includes all of the sizes and shapes you wish to produce and does not blow a hole in your budget. For example, if you are starting out, an automated machine is probably not the right choice for you.

How to choose (quick checklist):

- Throughput need — tabletop for companies producing hundreds of pre-rolls per day; industrial multi-head for thousands/day.

- Cone sizes / cartridges — make sure the machine supports your specific cone lengths (70/84/98/109mm are common).

- Filling method — simple vibration/tapping vs. weight-based or automated dosing.

- Integration — if you need to connect to upstream grinders or downstream tampers/packagers, prioritize vendors that offer line integration (STM, PreRoll-Er, Accelerant, industrial OEMs).

- A closer – Closing pre-rolls is the slowest part of production, so having a machine or closing tool that works with your cone-filling machine is key.

- Service & spare parts — It is important to maintain your investment and be able to replace any parts that may go bad.

Now let’s get into the machines themselves and what features each has so you can decide what works for you.

2025 Pre-Roll Cone Filling Machine Report - Machine Lineup

Buddies Bump Box

A manual cone-filling machine that requires employees to “bump” the box onto a sturdy surface in order to pack cones. Made with plastic or wood, depending on the size, this is a basic, starter machine that relies on the employee to ensure that pre-rolls are correctly and cleanly packed. Though effective, it is not particularly efficient.

- Capacity per cycle: 34 or 76

- Electronic: No

- Motor Type: N/A

- Cone Size Compatibility: 84mm, 98mm, 109mm

- Tube Compatibility: No

- Metering Tray: No

- Spare Parts Available: No

- one Closer Device: No

- Price: ~$40 - $150

Fast Fill 121

A small, multi-piece electronic cone-filling machine, the Fast Fill 121 is easy to use and scalable for multiple sizes of pre-rolled cone. Made of durable, hard plastic, the Fast Fill uses different cartridges for each cone size and is available in multiple hole counts.

- Capacity per cycle: 121 cones

- Electronic: Yes

- Motor type: Vibrating

- Cone Size Compatibility: 70mm, 84mm, 98mm, 98mm reefer, 109mm, 140mm

- Tube Compatibility: Yes

- Metering Tray: No

- Spare Parts Available: No

- Cone Closer Device: No

- Price: $449 - $749 (depending on cone cartridge size)

Fill ’N Fold

A small, multi-piece tabletop machine with a vibrating base and a unique closing tool that vastly speeds up throughput. Made with high density plastic with form-fitting conical chambers that create little waste, making it a very efficient machine, particularly when using the tamping and folding tool to speed up the overall process.

- Capacity per cycle: 121

- Electronic: Yes

- Motor Type: Vibrating

- Cone Size Compatibility: 70mm, 84mm, 98mm, 98mm Reefer, 109mm

- Tube Compatibility: Yes, with conversion kit

- Metering Tray: Yes

- Spare Parts Available: Yes

- Cone Closer Device: Yes, capable of closing 11 pre-rolls at one time

- Price: $2,500

King Kone

A small, highly versatile metal tabletop machine with an adjustable bounce motor and an available closing device. The King Kone comes ready-to-use for multiple sizes of pre-rolled cones and the collection trays along the sides collect any flower that may fall through, reducing waste.

- Capacity per cycle: 169

- Electronic: Yes

- Motor Type: Bounce (adjustable speed)

- Cone Size Compatibility: 70mm, 84mm, 98mm, 98mm reefer, 109mm

- Tube Compatibility: Yes, with conversion kit

- Metering Tray: Yes

- Spare Parts Available: Yes

- Cone Closer Device: Yes, purchased separately

- Price: $1,999

TPH-128, TPH-512

A small, modular, metal tabletop cone-filling machine that is available in two sizes. However, the TPH machines use brand- and size-specific cone trays, which means changing your trays may require not only a change to the size of pre-rolls, but also a new tray if you switch cone providers. However, because it is all metal, this machine is easy-to-clean, though the lack of a metering tray may lead to additional weighing and filling time on the back end, before closing.

- Capacity per cycle: 128, 512

- Electronic: Yes

- Motor Type: Vibration

- Cone Size Compatibility: 70mm, 84mm, 98mm, 109mm, 120mm, 140mm

- Tube Compatibility: No

- Metering Tray: No

- Spare Parts Available: Yes

- Cone Closer Device: No

- Price: $2,995, $5,145

Futurola KnockBox

A common tabletop cone-filling machine with a vibrating motor that uses glass tubes to hold cones in place. Though the KnockBox works with a variety of cones sizes and manufacturers, the glass tubes are fragile and make the machine difficult to use to fill cones with premium filter tips like ceramic or glass, which may damage the holders or cones during vibration cycles.

- Capacity per cycle: 50, 100 or 300

- Electronic: Yes

- Motor Type: Vibration

- Cone Size Compatibility: 84mm, 98mm reefer, 109mm

- Tube Compatibility: No

- Metering Tray: Yes

- Spare Parts Available: Yes

- Cone Closer Device: Yes

- Price: $3,000, $6,250, $15,625

The Reefer Ranger

A vibrating, multi-piece cone-filling machine with an adjustable motor, designed and built specifically for 1-gram 109mm cones. It consists of a molded, high-density plastic cone holder that sits on top of a clear vibration table with an exposed motor underneath.

A Foldover Attachment is available for each model to help speed closing cones.

- Capacity per cycle: 200, 320, 420

- Electronic: Yes

- Motor Type: Vibration

- Cone Size Compatibility: 109mm

- Tube Compatibility: No

- Metering Tray: Yes

- Spare Parts Available: Yes

- Cone Closer Device: Yes

- Price: $2,799, $4,250

STM Mini-RocketBox PLUS+

An electronic, stainless steel machine shaped like a cube with an adjustable vibrating motor. The RocketBox line uses a single tray system that is compatible across multiple machines that help meter, fill, weight, close and even infuse.

- Capacity per cycle: 72-143 cones per hour.

- Electronic: Yes

- Motor Type: Vibration

- Cone Size Compatibility: 70mm, 84mm, 98mm, 109mm.

- Tube Compatibility: Yes, with tray.

- Metering Tray: Adjustable vibration/leveling trays for fill accuracy; smart-density software.

- Spare Parts Available: Yes; trays, vibration plates, belts, and motors.

- Cone Closer Device: Separate closing machine available

- Price: $6,600

Hummingbird PR-1 Centrifugal Pre-Roll Machine

The Hummingbird PR-1 Pre-Roll Machine uses a revolutionary centrifugal motor that uses the power of centrifugal force to put higher-density material near the crutch and a smooth density gradient. It is a metal machine that uses color-coded molded plastic pods to hold cones for filling. It also has a variety of color-coded accessories, including tampers and ejector plates that work to help speed up the process.

- Capacity per cycle: 120

- Electronic: Yes

- Motor Type: Centrifugal

- Cone Size Compatibility: 84mm, 98mm, 109mm

- Tube Compatibility: Yes

- Metering Tray: Yes

- Spare Parts Available: Yes

- Cone Closer Device: No

- Price: $15,000

STM Canna RocketBox

A high-capacity, industrial sized version of the Mini RocketBox designed for large manufacturers, white labelers and co-packers. It has the same single tray design that can be moved to weigh and close the pre-rolls and multiple adjustable vibration motors. Made of steel and aluminum, the RocketBox is durable and easily cleaned and because it has a multi-station design, it can be used to fill multiple sized cones at the same time.

- Capacity per cycle: 72-453

- Electronic: Yes

- Motor Type: Vibration

- Cone Size Compatibility: 70mm, 84mm, 98mm, 109mm

- Tube Compatibility: Yes

- Metering Tray: Adjustable vibration/leveling trays for fill accuracy; smart-density software.

- Spare Parts Available: Yes

- Cone Closer Device: Separate machines available.

- Price: $59,950

Accelerant PRO2

A scalable, fully automated pre-roll machine designed for high throughput manufacturing that weighs, fills and closes with minimal employee supervision, with a touch screen and additional data collection and reporting.

- Capacity per cycle: 1,000+ per hour

- Electronic: Yes

- Motor Type: Automated

- Cone Size Compatibility: 98mm, 109mm, 120mm

- Tube Compatibility: N/A

- Metering Tray: Built-in

- Spare Parts Available: Yes

- Cone Closer Device: Built-in

- Price: Contact for quote

Hefestus AuraX

A fully automated, high-capacity pre-roll filling machine that uses vibration and has a Dutch crown closer, built to handle infused flower. It has a touch screen and optional weight-checker, but requires a specific particle size as input.

- Capacity per cycle: 1,500+ per hour

- Electronic: Yes

- Motor Type: Vibration

- Cone Size Compatibility: Uses a single paper size and cuts to various lengths

- Tube Compatibility: Yes

- Metering Tray: Built-in

- Spare Parts Available: Yes

- Cone Closer Device: Built-in Dutch Crown fold

- Price: Contact for quote

RollPros Blackbird™

Though not a cone-filling machine, the Blackbird™ is an automated pre-roll machine that uses bobbins of rolling paper and filter tips to roll joints. The machine has a touch screen for repeatability and is connected to the cloud for data collection and reporting.

- Capacity per cycle: 900 per hour

- Electronic: Yes

- Motor Type: N/A

- Cone Size Compatibility: N/A

- Tube Compatibility: This machine rolls tubes

- Metering Tray: Built-in

- Spare Parts Available: Yes

- Cone Closer Device: Built-in

- Price: Contact for quote

PreRoll-Er

A high-capacity, fully automated pre-roll machine that fills, compacts, weighs twists and cuts, creating fully-finished pre-rolls with minimal human interaction.

- Capacity: About 1,300 per hour

- Electronic: Yes

- Motor Type: Automated; layered compaction

- Cone Size Compatibility: 0.25- to 3.0-grams

- Tube Compatibility: Yes

- Metering Tray: Built-in

- Spare Parts Available: Yes

- Cone Closer Device: Built-in

- Price: Contact for quote

Final Thoughts on Pre-Roll Machines

So what’s the best machine? Again, that depends. We find that smaller, tabletop electronic machines like the King Kone and Fill N’ Fold tend to be the best for small- to medium-sized pre-roll producers.

Both are versatile machines with a small footprint and a low cost. They are easy to learn and maintain and can produce large numbers of pre-rolls with just a few operators.

While the King Kone’s adjustable bounce motor and tray system provides for a wider range of products, the Fill N Fold’s revolutionary closing tool speeds up the finishing process and gives that machine an edge in production numbers, though the King Kone Dutch Crown Closer does help close the gap.

Again, this comes down to preference for your business. Contact the Pre-Roll Experts today to discuss which cone-filling machine makes the most sense for your brand and business.

When it comes to your pre-roll production line, perhaps the most important decision you have to make is your cone filling machine.