Testing the “Holes Fallacy”: A Comparative Study of Pre-Roll Machines

Posted by Custom Cones USA on Jul 18th 2024

Choosing the right cone filling machine for your production line is one of the most important decisions any pre-roll manufacturer can make. There’s no easy answer and there are many different things to be factored in before selecting the pre-roll machine that’s right for you.

But one of the most basic and important pieces of data that need to be considered is the throughput of whatever machine you choose; How many pre-rolls can your team produce in an hour?

The Holes Fallacy

Unfortunately, many businesses simply choose the machine that has the most holes or slot for pre-roll cones, based on the idea that “more holes must equal more pre-rolls." Seems easy enough, right?

Wrong. This is what we call “The Holes Fallacy.”

The truth is that there are a variety of factors that go into throughput. And while it begins with the number of pre-rolled cones or pre roll tubes any given machine can produce during a single packing cycle, it also includes employee experience, run time and, most importantly, how you close and finish your pre-rolls.

In fact, that last step – closing the pre-roll – is what we hear all the time as the biggest pain point and time-consuming part of pre-roll production. And you are only going to be able to produce pre-rolls as quickly as your slowest station on your production line.

So we decided to run an experiment to find out once and for all which cone filling machine allowed us to produce the most completed pre-rolls.

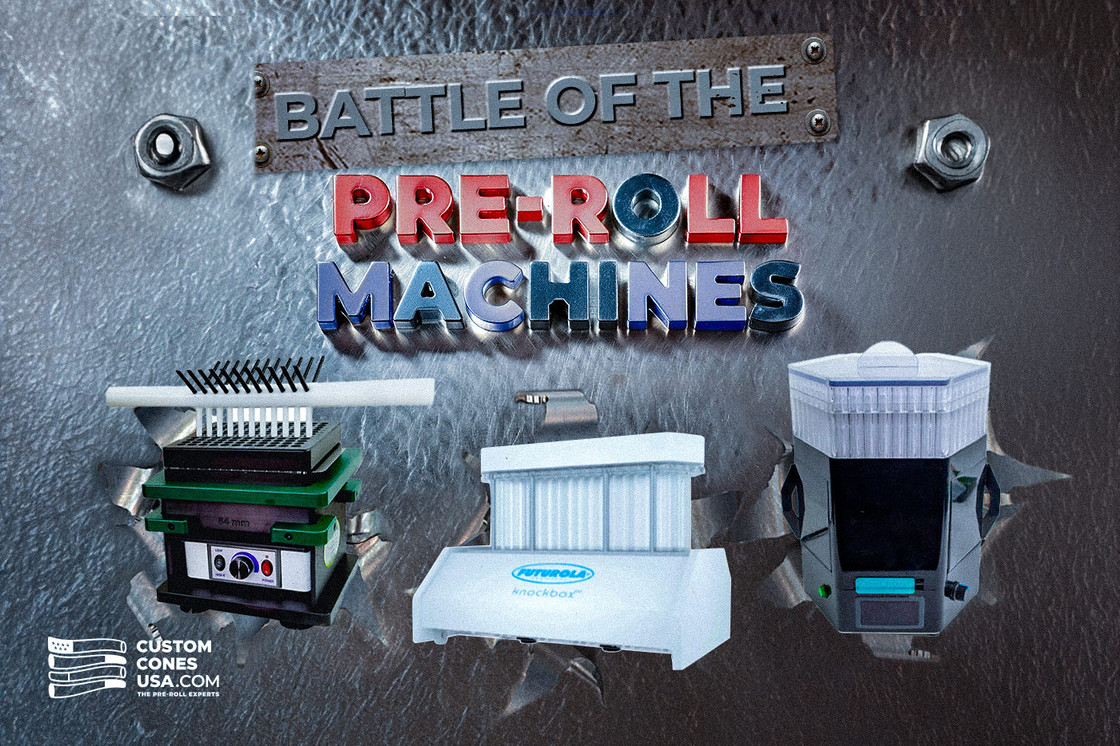

For our experiment, we tested the efficiency of three popular pre-roll machines: the Fill N' Fold, King Kone, and Knockbox. Our goal was to determine the number of pre-rolls each machine could produce per hour regardless of the number of holes. So which machine produced the most pre-rolls in an hour?? Read on...

Experimental Setup

We ran each cone filling machine three times under two sets of conditions. The first test involved a single operator, while the second incorporated two operators and additional spare parts. This setup allowed us to assess how efficiency could be increased with additional resources.

The same operator – one of our Pre-Roll Experts who is well-versed in providing demos of our cone packing machines – ran each experiment. For the two-person tests, the same secondary operator was also used each time.

We used 84mm, half gram cones for the experiment and used volumetric metering trays with each machine to help speed the process. The flower was all ground and sifted ahead of time using the Industrial Cannabis Grinder and Quick Sift Commercial Sifter to ensure a uniform particle size.

The Cone Filling Machine Competitors

We ran our trials on three cone filling machines: the King Kone, The Fill N’ Fold and the Futurola Knockbox 100. While similar, each machine has its own unique properties and method of filling.

The Fill N’ Fold cone filling machine uses vibration to fill up to 121 cones per cycle. It comes with a special tamping tool designed to help tamp down the flower and then fold down the tops of all your filled cones at the same time, creating a “Dutch crown” style finish. While the motor is the same, separate work trays and metering trays are needed for each size cone. The Fill N’ Fold retails for $2,500.

The King Kone is a versatile cone-filling machine with the ability to pack up to 169 pre-rolled cones in each cycle. It has a powerful motor that uses vertical motion to pack pre-rolled cones of any size, though metering trays for each size pre-rolled cone must be purchased separately. It comes with a tamping tool that was used as part of the experiment. Cones must be closed by hand (we used a twist). The King Kone retails for $1,399.99.

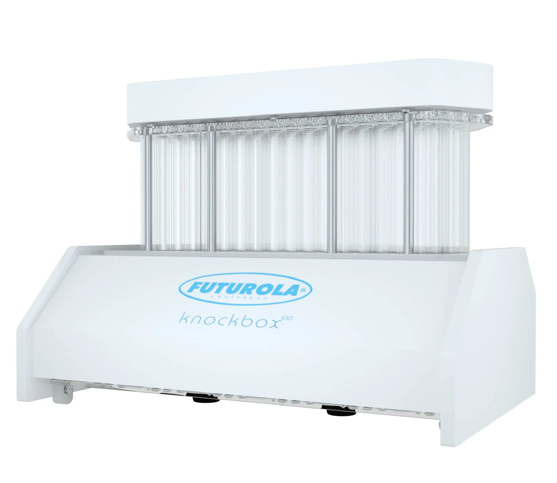

The Knockbox 100 uses vibration to fill up to 100 pre-rolled cones per cycle. It is compatible with multiple different cone sizes. A volumetric “filling kit” can be purchased, though it is not size-specific, so any flower that does not fit in the cones you are filling falls around the machine during use. Cones were closed by hand with a twist. The Knockbox retails for $6,250 and the Filling Kit costs an additional $1,875.

How We Conducted the Pre-Rolled Cone Filling Experiment

We ran full cycles on each machine three times with one operator and then three more times with two operators.

To get our results, we took the total amount of pre-rolls produced through the three cycles, and divided by the total amount of time it took to complete all three runs, including closing the pre-rolls to make sure we recreated the entire production process.

That gave us the number of pre-rolls produced per minute. We then multiplied that number by 60, giving us the average number of pre-rolls produced per hour.

Results of our Pre-Roll Filling Experiment

In the single operator test, the Fill N' Fold produced an average of 837 pre-rolls with a Dutch crown finish per hour, the King Kone produced 585 pre-rolls that were twisted closed per hour, and the Knockbox produced 529 pre-rolls with a twist close per hour.

When we added a second operator and spare parts, the Fill N' Fold's output increased to 1,361 pre-rolls per hour with a Dutch crown finish. The King Kone followed with 1170 completed pre-rolls and the Knockbox produced 1000 cones per hour, both with a twisted finish.

So as we see, the machine with the most holes – the King Kone – did not win. In fact, it got smoked by the smaller Fill N’ Fold, producing a similar number of completed cones to the Knockbox, disproving once and for all the “holes fallacy” that more cones per cycle results in more completed pre-rolls.

Key Observations

The difference in output between these machines came down to the closing techniques.

The Fill N' Fold's unique folding tool enabled it to produce pre-rolls with a Dutch crown finish, whereas the King Kone and Knockbox pre-rolls were twisted closed. Speed was prioritized in our tests, so we left the excess paper on the twisted pre-rolls.

Additionally, the introduction of a second operator and spare parts significantly boosted the output of all three machines. The Fill N' Fold saw the most considerable increase, followed by the King Kone and then the Knockbox. Again, despite having fewer holes, the Fill N' Fold's tamping and folding tool allowed it to outperform the other machines in both trials, even with a second operator twisting the completed pre-rolls.

More Holes ≠ More Ouput

When selecting a pre-roll machine for your business, it’s important to remember that more holes don't necessarily mean higher output. The Fill N' Fold, with its innovative tamping and folding tool, proves this point by delivering the best throughput per hour despite having fewer packing slots than the King Kone.

Furthermore, to enhance your manufacturing process, consider adding spare trays and parts instead of immediately investing in a second machine. Introducing a third employee and additional parts could further increase your output before needing to scale up to another pre roll machine.

Also, while your team may produce more or less pre-rolls per hour than ours, depending on how experienced they are and your exact manufacturing process, but these numbers are directional, meaning if your team currently produces 20% more pre-rolls than we did on the Knockbox or King Kone, they should be able to produce even more on the Fill N’ Fold or by adding spare parts to your current process.

By optimizing your resources and understanding the capabilities of your equipment, you can significantly improve your pre-roll production efficiency.

But whatever cone filling machine you choose, pay no attention to the Holes Fallacy. Remember: more holes does not always mean more pre rolls. Contact the Pre-Roll Experts today to figure out which pre-roll cone packing machine is right for you.

Choosing the right cone filling machine for your production line is one of the most important decisions any pre-roll manufacturer can make. There’s no easy answer and there are many different things to be factored in before selecting the pre-roll machine that’s right for you.