Cleaning the King Kone Pre-Rolled Cone Filling Machine

Posted by Custom Cones USA on Oct 24th 2025

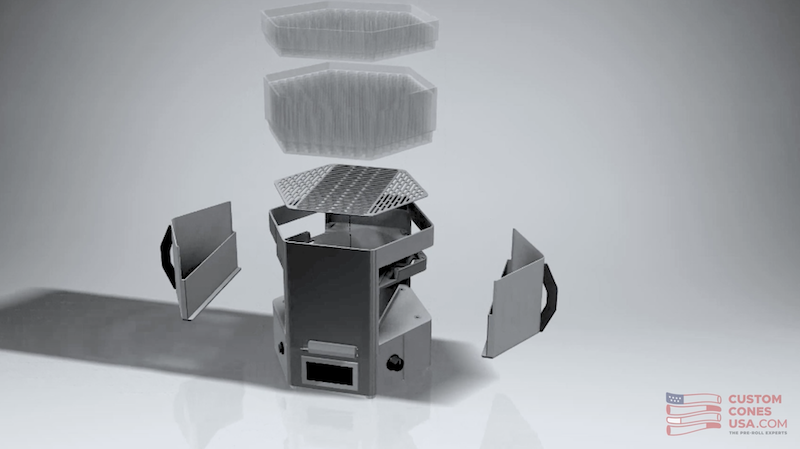

The King Kone Cone-Filling Machine is one of the most versatile and easy-to-use pre-roll machines on the market, capable of producing up to 169 pre-rolls of just about any size in seconds, right out of the box.

But ensuring your King Kone keeps churning out high-quality pre-rolls means more than filling it with top-quality pre-rolled cones and premium flower. Because, after all, if the machine is working right, then none of the rest of that matters.

Which is why it is important to employ a maintenance routine that includes regular cleanings to make sure your King Kone remains in optimal condition.

So how do you clean a King Kone Cone-Filling Machine? Don’t worry, the Pre-Roll Experts got you.

Why You Need to Clean the King Kone Cone Filler

The simple fact is that cannabis is sticky. The resins and oils that we so value as consumers are the same substances that can gum up machinery. From the smallest hand grinders to the largest automated cone-filling machines, every pre-roll machine will eventually need to be cleaned or it will stop working properly.

That includes the King Kone, whose moving parts can become covered in resin from trichomes broken open during the bouncing that packs the flower into the pre-rolled cones. Unless properly cleaned from time to time, these moving parts will seize up.

A clean King Kone performs better, lasts longer and safeguards product integrity. Neglecting cleaning leads to buildup that can slow production, cross-contaminate different strains, and potentially even allow microbes to grow between batches.

By implementing regular cleanings, you minimize downtime, ensure compliance, and protect your investment. Ideally, cleaning should be done at the end of each shift, or at the very least once a week for lower-volume operations.

Thankfully, the King Kone’s modular design and metal construction make cleaning simple and fast.

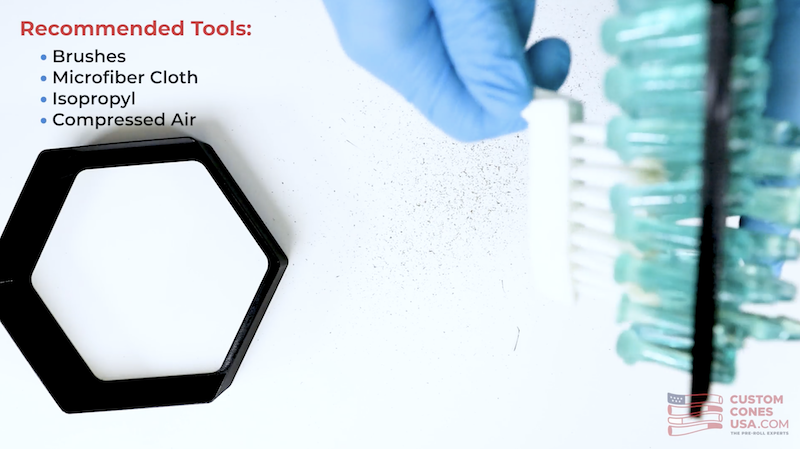

Recommended Tools for Cleaning the King Kone

Before getting started, it’s important to have on hand all of the tools you need to effectively clean the King Kone. You will need:

- Tube brushes and wire brushes;

- Gun-cleaning brushes;

- Clean cloths and towels;

- Compressed air; and

- Up to 95% isopropyl alcohol.

Protecting yourself and your employees is equally as important as the machine. So while cleaning, always wear proper PPE, including goggles and a mask, and clean the machine in a well-ventilated area with an appropriate air filtration system.

Ok, now we’re ready to begin.

How to Clean the King Kone Pre-Rolled Cone Filling Machine

The first thing to remember when cleaning your King Kone is that certain components of the King Kone, such as the work trays, are industrially 3D printed, and cannot simply be soaked in water as they can absorb some of that moisture. This increases the risk of microbial growth on those parts if they aren’t properly dried during the cleaning process.

Instead, use a damp cloth or isopropyl alcohol to wipe down the work trays and use a tube brush and alcohol to clean the individual slots. Be sure to let it fully dry before use. Now, for the machine itself, start from the top and work your way down.

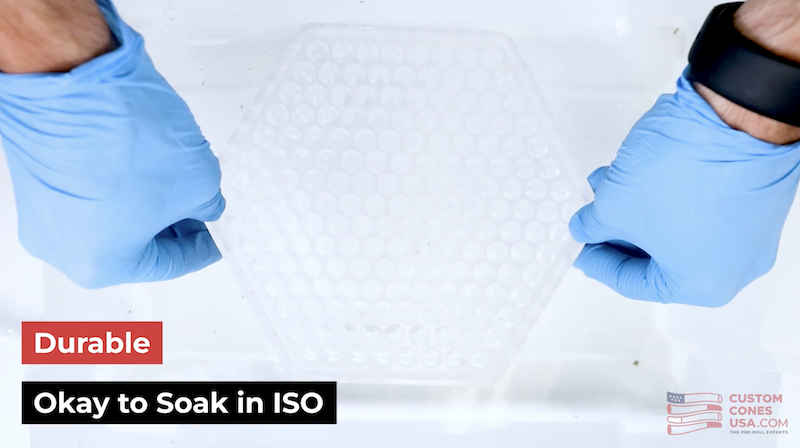

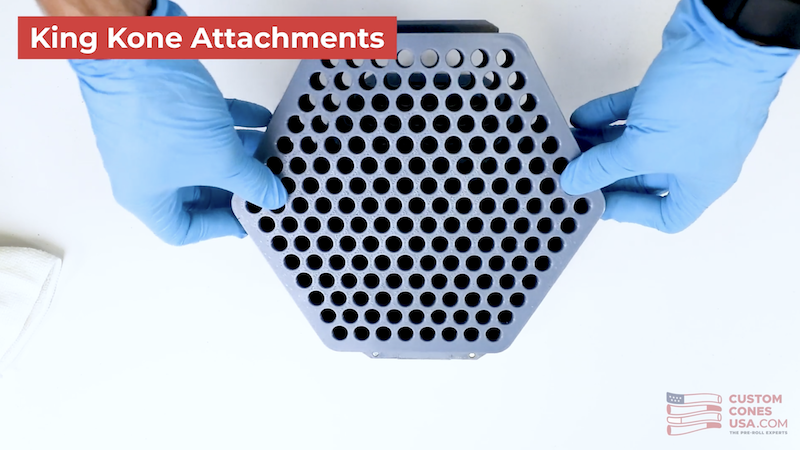

Begin by removing the durable, polycarbonate top trays. These clear trays can safely be soaked in isopropyl alcohol because they don’t absorb moisture. Let them soak for about 10 minutes or so and then use a toothbrush for final cleaning, or you can use alcohol on the brushes and on cloths to wipe down and through all of the parts and the openings in them.

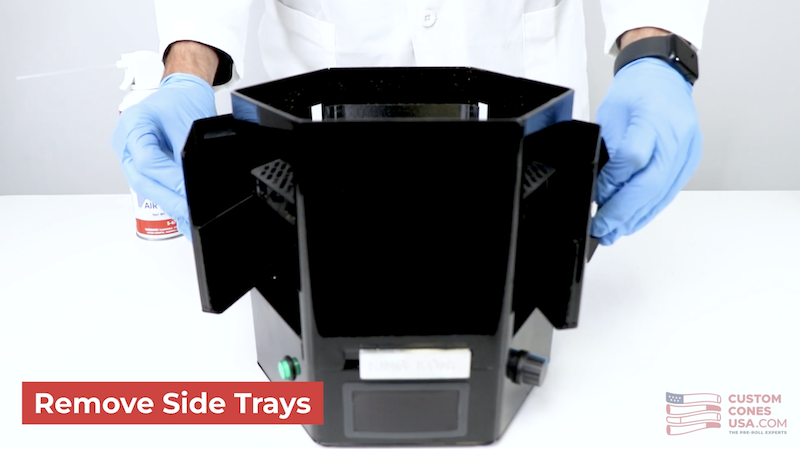

One of the unique features of the King Kone is the addition of the collector trays on the side of the machine that are there to catch any flower that may fall out or through during packing. The side trays are made from powder-coated stainless steel. To clean these, grab a cloth or brush and use up to 95% isopropyl alcohol to clean any buildup or residue from all the surfaces and crevices.

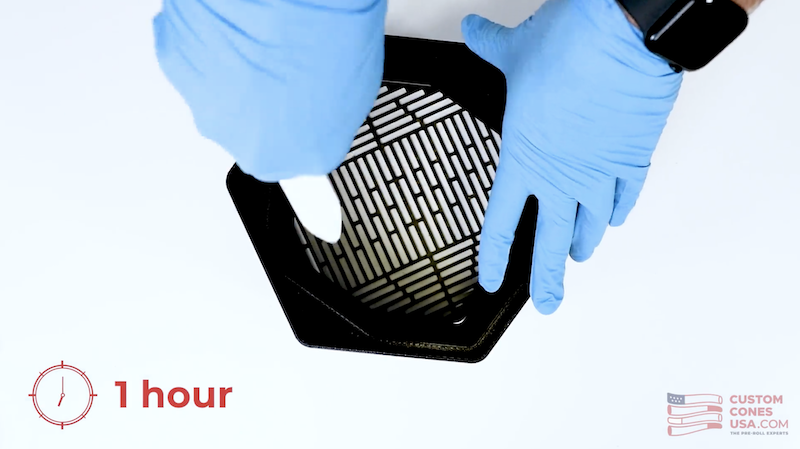

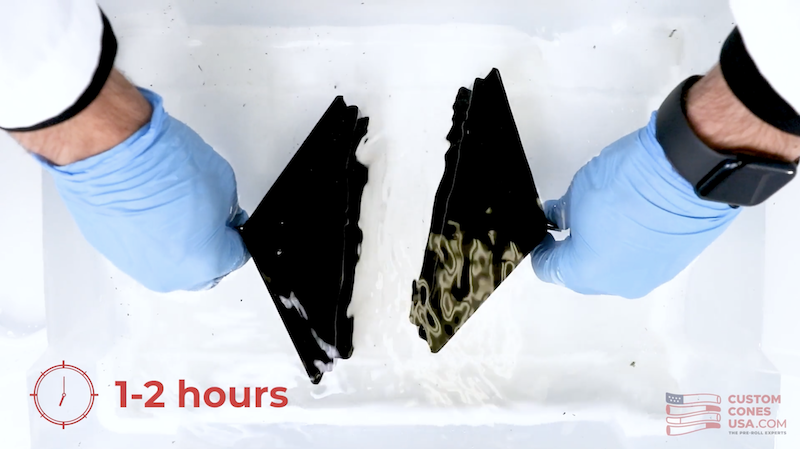

Inside the King Kone, you’ll notice a metal plate where excess flower material tends to collect. This plate is made from cold-rolled steel, so it can also be soaked. However, only soak it for about an hour, then scrub it thoroughly and make sure it’s completely dry before reassembly.

For the housing of the King Kone – the main metal body surrounding the motor – the best cleaning method is to scrub it with a brush. Remove the housing by unlocking the two tabs at the front and back of the machine. Like the trays, the housing is made from powder-coated stainless steel, so it’s durable and can be soaked in water or isopropyl alcohol (up to 95%). After scrubbing, make sure to dry it completely.

Finally, use compressed air to remove any remaining debris and moisture. This will help ensure your King Kone runs smoothly and stays in great condition.

How to Clean the King Kone Attachments

One of the best features of the King Kone is its wide variety of attachments, which allow you to scale your pre-roll line and create new products. It’s essential to keep these attachments clean as well.

We recommend making it part of your Standard Operating Procedure (SOP) to clean the machine and accessories at the end of each shift. This follows proper manufacturing best practices. If that’s not possible, clean everything at least once per week.

King Kone Tube Conversion Kit

One of the most useful attachments for the King Kone cone-filling machine is the Tube Conversion Kit, which allows you to pack pre-rolled smoking tubes with the same machine you use to pack your pre-rolled cones.

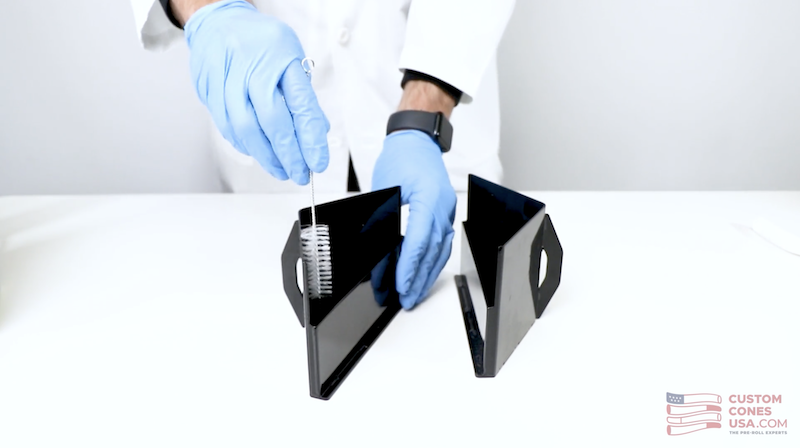

To clean conversion kits:

- Use tube brushes to scrub each slot.

- Dip brushes in isopropyl alcohol for a deeper clean.

- Finish with compressed air to remove fine debris and moisture.

Cleaning the Metering Tray

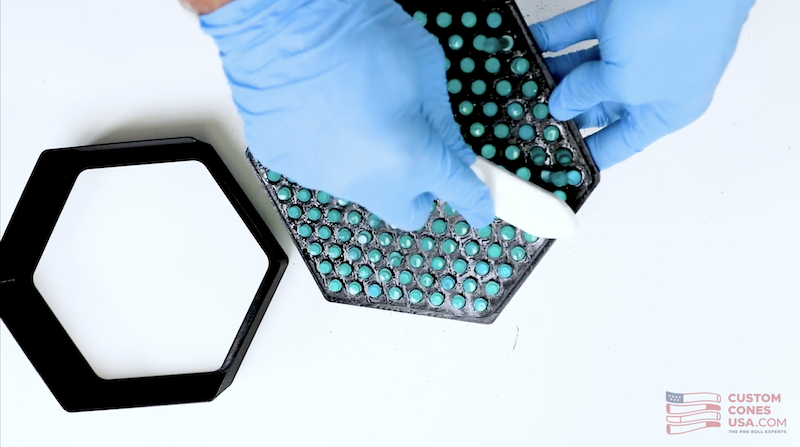

Volumetric metering trays are a great way to ensure that each of your pre-rolls is filled evenly, saving time on the backend and helping you stay in compliance. But like everything else, those metering trays also need to be kept clean to make sure each slot contains and drops the same amount of flower.

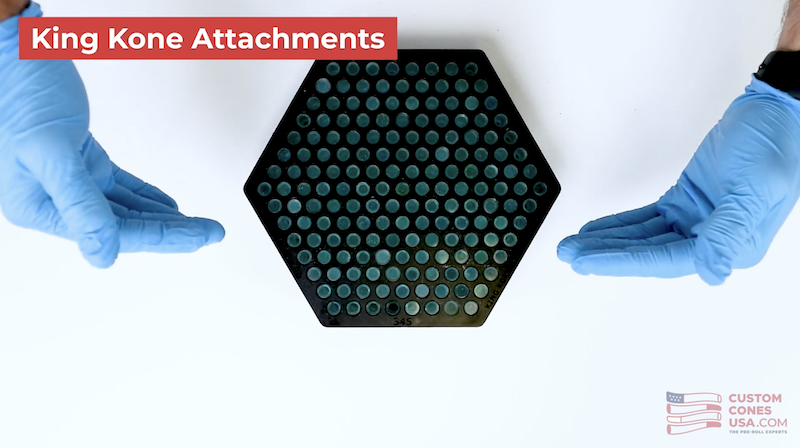

To clean the metering tray, remove the metal slide from inside and separate the top and bottom halves. Use a brush to scrub each hole in the tray and clean the metal surfaces thoroughly, as these parts can easily build up residue from contact with flower material.

As with all other components, don’t soak for too long. Finish by using compressed air to dry and remove any remaining particles.

Remaining King Kone Attachments

Any other attachments or parts you have for your King Kone machine should also be regularly cleaned to keep them working smoothly. Focus especially on any flower-touching parts to prevent cross-contamination.

Plastic parts may discolor over time from repeated cleaning, but this is purely cosmetic. Also, and this is important, never place plastic components in a dishwasher. The water in a dishwasher gets too hot and can damage the plastic on attachments like the tamping fingers.

Instead, clean these parts with brushes, cloths, and isopropyl alcohol. Be sure to give these parts a good scrub with the brush to get all bits of flower or resin off and then dry thoroughly with compressed air.

Final Thoughts on Cleaning the King Kone

Regular cleaning ensures your King Kone continues to perform at its best. Neglecting maintenance can degrade performance, slow down production and cause cross-contamination between different strains.

In the worst cases, it can allow microbial growth from batch to batch.

As a reminder, do not soak the parts in water for extended periods. If you clean your machine regularly – and you should – you can avoid the need for long soaks altogether. When soaking is necessary, limit it to about one hour and always make sure every component is thoroughly dried before use.

Your King Kone is a precision machine designed to streamline pre-roll production, but like any piece of equipment, its performance depends on proper care. A regular cleaning schedule will keep your production line running smoothly.

Treat cleaning not as a chore but as a key part of your manufacturing best practices, and your King Kone will reward you with reliability, consistency and clean, efficient output, batch after batch.

And of course, you can always contact the Pre-Roll Experts at Custom Cones USA with any additional questions or concerns you may have.

It's important to employ a maintenance routine that includes regular cleanings to your King Kone to keep it running optimally.