The fastest, easiest way to coat your infused pre-rolls before adding kief! Designed by the industry for the industry, the KL120 Automated Infused Joint Coating Machine is a small, tabletop pre-roll machine that can coat any size finished pre-roll (up to 120mm) with adhesive or distillate in less than 3 seconds, speeding your pre-roll process, freeing up employee time and drastically increasing your infused pre-roll throughput. With two stainless steel roller housings and reservoirs, each with its own temperature control and a pair of rollers allowing either side of the machine that coats two pre-rolls at a time, the KL120 offers a precision and repeatability that is difficult for employees to match. Fast, easy and compact, the KL120 Automated Infused Joint Coating Machine is a must-have for any brand looking to launch or scale their infused pre-roll line.

With the ability to coat up to 7,000 infused pre-rolls per hour, the KL120 Automated Infused Joint Coating Machine is the fastest way to prepare your pre-rolls to be covered in kief. The KL120 can coat 4 of any size pre-roll (up to 120mm pre-rolled cones) at one time in just seconds, saving both employee hours and money while providing a precise and repeatable process designed for scalability.

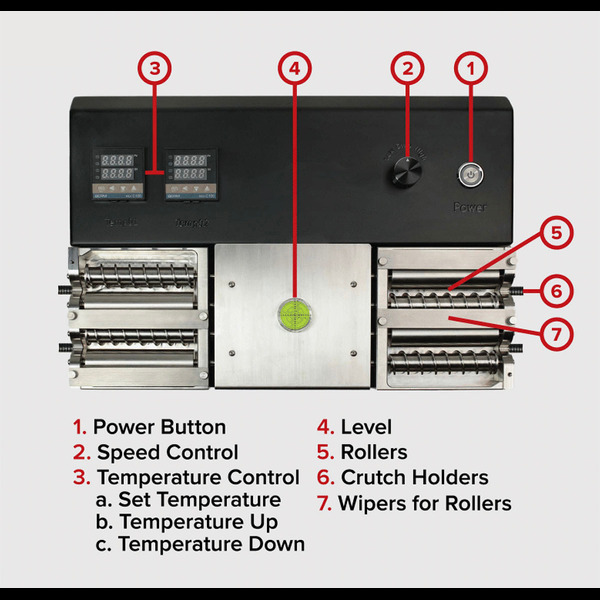

The KL120 Automated Joint Coating Machine features two stainless steel reservoirs, each with its own temperature control system showing the current temp and the goal temp, so manufacturers can perfectly dial-in their procedures every time. We have found the KL120 works best with adhesives, such as gum arabic or pre-mixed glues, but will work also with distillate.

With space for two employees at a time, the KL120 is a simple, fast pre-roll infusion machine that is easy to use and saves hours of employee time. Workers simply place a packed pre-roll on one of the rollers with the crutch on one of the adjustable crutch holders, then let it rotate about three times, or about 2 seconds, coating the outside with your adhesive. That’s it! It’s ready to be coated in kief!

With an employee manning each of the dual-roller reservoirs, manufacturers can produce between 4,500-7,000 infused pre-rolls per hour.

The KL120 will coat any size pre-rolled cone up to 120mm in length or 20mm in diameter.

The KL120 is 15.75” by 11” by 6.25” big and weighs 45 pounds.

We have found the KL120 works best with adhesives, such as gum arabic or pre-mixed glues, but will work also with distillate.

Each reservoir holds and heats up to 160 milliliters of adhesive of ditillate.

We recommend a temperature around 30 degrees Celsius or 85 degrees Fahrenheit, which though warm is still safe to the touch and keeps the adhesive or distillate flowing freely.