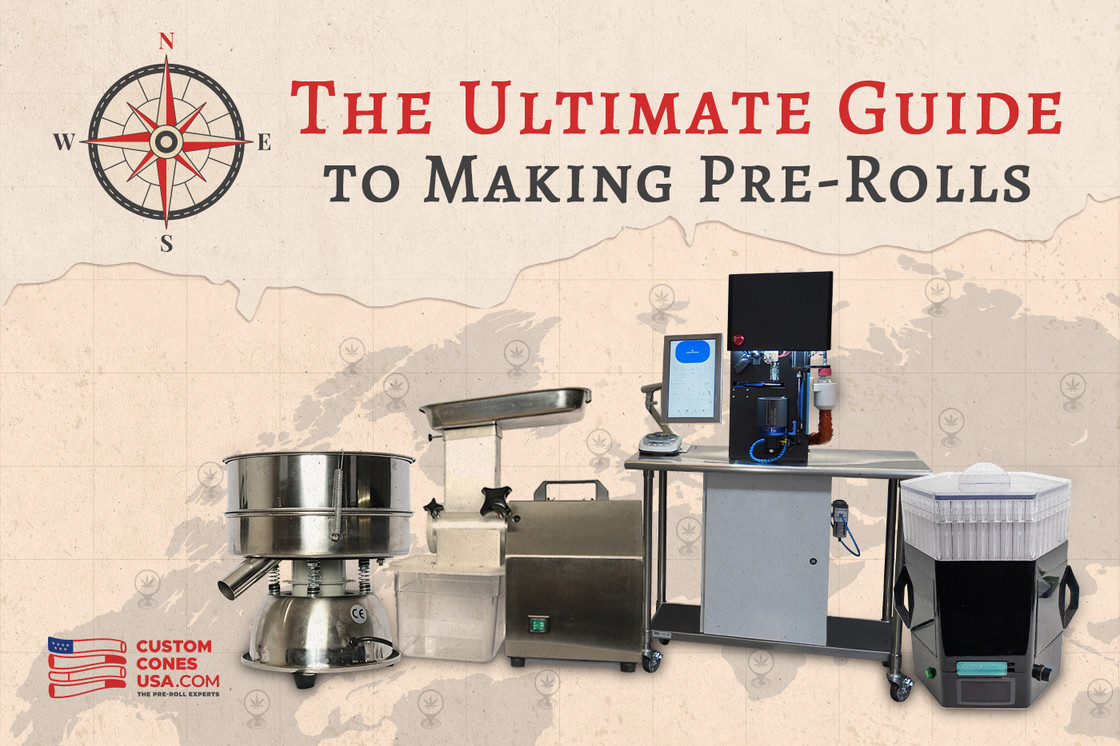

How to Make Pre-Rolls: The Ultimate Guide

Posted by Custom Cones USA on Feb 1st 2023

Like all cannabis products, the process for making pre-rolls begins with the cannabis plant, specifically cured flower. The plant can be manipulated to produce any number of products, so when it comes to making pre-rolls, there is a long list of considerations before you even begin putting flower to paper.

It All Starts with the Grind

The flower needs to be dried and cured properly, ground into appropriately sized particles, and sifted to get rid of any unwanted particles, stems, or leafy material. Only after all this has happened can you begin to think about filling, sealing, and packaging your final product, and that’s exactly why we created this pre-roll manufacturing guide—to give you a step-by-step breakdown on how to produce a pre-roll, scale your pre-roll manufacturing process, and create new pre-roll products!

Below you will find everything you need to get started producing the best pre-rolls. Each step is broken down so you know exactly what you’ll need to get going. If you want to speak with a professional, feel free to reach out to our team of Pre-Roll Experts – we are always happy to answer all your questions.

Flower: The Starting Material

There are a lot of different methods that cannabis producers use to grow their cannabis, and they all have personal preferences on how they want their final product to look. Here at Custom Cones USA, we like to leave those choices to the expert growers (you); however, allow us to give some of our expert guidance on what it means to turn your wonderful buds into a pre-roll.

Regardless of how you grow your cannabis, there are steps you are going to need to take to ensure that your pre-roll production goes smoothly. Firstly, you need to make sure that your starting material has been properly dried and cured. As you are already aware, this will ensure that the flower does not mold after it has been sealed. It will also ensure that it doesn’t turn to dust through the pre-roll grinding and production process, because it is too dry. Making sure you use properly cured flower in your pre-rolls will also ensure higher terpene levels, which makes your pre-rolls smell and taste better.

Grinding Machines

A lot of time goes into growing quality cannabis flower. So, when it comes time to grind it down to make a pre-roll, you should make sure that you’re doing it in a way that preserves its integrity. For example, a high rpm (Rotations per Minute) grinding machine, like a blender, food processor, or coffee grinder will produce heat due to the fast blade speed and friction. This leads to the bud getting warmed and pulverized to dust, which not only degrades cannabinoids and terpenes, but too finely ground flower causes pre-rolls to burn harsher and clog more frequently. Using a blender or food processor type grinder also leads to uneven particle sizes, where you get some big chunks, some nicely ground flower, and too much finely ground dust.

It’s easy to see why you’d want to avoid a process that will degrade your bud with heat, but you also want to make sure you get a consistent grind. An inconsistent grind will cause a pre-roll to be packed unevenly and cause the joint to burn unevenly. Using this type of uneven material will also slow down your pre-roll manufacturing process and create pre-rolls with more inaccurate weights vs sifted cannabis flower.

In order to ensure a consistent grind that won’t degrade your flower, we recommend using a grinder that has a low rpm, a lot of torque, and screens that will ensure buds are ground into a consistent size. High torque and low rpm will provide the lowest amount of stress to the bud and, therefore, help preserve the terpenes and full cannabinoid profile.

Made from stainless steel and all food-grade materials, our industrial grinder is built like a tank. The stainless-steel blades are removable and easy to clean, and the entire unit can be taken apart quickly and cleaned with alcohol. Each grinder comes with three screen sizes and all parts are replaceable. In other words, it has everything you need to get the perfect grind.

For larger operations or manufacturers with automated pre-roll machines – we offer two larger sized pre-roll milling solutions. Designed to get through some serious weight, the Industrial Grindsizer and the Mega Industrial Grinder can process hundreds of pounds of plant matter a day. They also have adjustable motor speeds to avoid degradation, a variety of screen sizes to make sure you get the grind just right, and are made of stainless steel to ensure that cleanup is a breeze.

Sifting Machines

Sifting is something that can get easily overlooked; however, it can save you a lot of headaches further down the production line. Its main purpose is to create a uniform particle distribution from your ground material, as well as remove any stem fragments. Care needs to be taken in making sure you don’t over-sift and separate the trichomes (kief) from the flower. That being said, if you wanted to make kief or hash, dry sifting is a way to get that done and our automated cannabis sifters are perfect for scaling your production.

In short, a sifter is about quality control. After your flower goes through the grinder, there still might be things that you don’t want in your pre-rolls. For example, a sifter will make sure that things like stems won’t make it into your pre-rolls, as stems will make your pre-rolls harsher, less potent, and have the potential to cause a tear in the paper during production. Sifters also keep very small particles out of your pre-rolls, which can ruin the smoking experience by creating a hotter burning pre-rolls and even clog by restricting air-flow down the pre-roll.

We offer a wide variety of Industrial Sifters that can meet the demands of any size operation. So, don’t hesitate to reach out and speak with one of our experts about which machine will be perfect for you.

Pro Tips

#1: Collect all kief after the

sifting process and mix back with the sifted flower material. Particles tend to

settle over time, so products should be mixed if stored for future production.

#2: After grinding and sifting your flower, it

is a good idea to allow the bud to dry/cure again. The grinding process is

going to agitate the trichomes and cause the flower material to be extra

sticky. This is going to cause issues down the line, when it comes to

assembling the pre-rolls. Instead of letting the sticky buds gunk up your production line/machines, give the material oils in the material

to get settled.

Pre-Roll Manufacturing

You’ve spent the time growing/sourcing the bud, and you’ve been extra careful to make sure it retained its integrity throughout the drying, curing, grinding, and sifting processes. The time has finally come to turn it into a pre-roll!

Pre-Roll Production Myth

Before we get into your options for filling your cones/tubes, there is a myth that needs to be busted. Too much emphasis is often put on the size of the cartridge or number of holes that get loaded into the pre-roll machine. Many people assume that the more cones/tubes a cartridge can hold, the faster they will be able to produce pre-rolls; however, this is not necessarily the case.

The amount of time it takes for one pre-roll to get done (cycle time) and the amount of time it takes to get a whole cartridge done (throughput) is dependent on a lot more than the cartridge size. You have to consider every point of your production process. For example, even if you can fill 1,000 pre-rolls every ten minutes, you aren’t going to be producing 6,000 an hour if you don’t have enough people filling the cartridges, or you don’t have enough people finishing the pre-rolls (twisting, packaging, etc.), so they start to back up.

Based on your production needs and staffing options, in most cases, it is better to have smaller machines with multiple trays. This allows trays to be filled as others are being filled by the machine. This also allows batches to be smaller and keep things from backing up further down the production line. In short, before you pick the biggest machine, consider how your production line will run, and, if you need some advice, the Pre-Roll Experts at Custom Cones USA are always here to lend a helping hand in finding the perfect machine for you.

Pro-Tip: Use multiple cartridges in your pre-roll machine to increase your capacity. It is often better to run more trays in a smaller machine than using a larger machine, as the times to load the cones and fill the flower is the same no matter if your machine has 100, 169, or 300+ holes.

Manufacturing Hemp Wrap Blunts at Scale

Finding the right size pre-roll for your brand has more to do with personal preference than the ability of our pre-roll machines. Cones that can hold one gram of flower are the most popular option in pre-roll production, but all our machines are adjustable enough to make any size work.

Something that is often forgotten about in the production process is the paper—specifically the storing needs of those products. Our traditional papers (primarily made from plant cellulose) are super easy to store, as nothing else is required other than to keep them in a dry place with a consistent temperature and humidity. Hemp-based papers, on the other hand, require a little more maintenance to ensure successful production and optimal enjoyment for your customers.

Hemp paper is a lot more sensitive to changes in temperature and moisture. Hemp papers that are exposed to open air and/or high temperatures will quickly become brittle. This will make it exceptionally hard to use in production. It also makes for a harsher smoke. If the papers have too much moisture, it is easy for them to develop mold and fail testing. The last thing you want to do is produce something that can’t be sold because it failed compliance or broke to pieces as someone was trying to smoke it.

The easiest way to ensure that your hemp paper cones remain perfect is to keep them in a humidor—similar to the way a cigar is stored to retain freshness. A humidor will keep the humidity at an optimal level, and this will make sure that the hemp paper remains moist enough to be pliable but not moist enough to encourage mold.

What’s really cool about these machines is that they bring dried out paper back to life. In other words, even if you leave papers out and they get too dry, you will be able to put them back into the humidifier and they will rehydrate. This can save you from needing to throw away parts of your inventory. There is, however, no way to come back from mold. So be extra vigilant when it comes to keeping your products from getting too much moisture.

Pre-Roll Machines

Now that all the prep work has been done, the time has finally come to bring it all together. Let’s take a closer look at the machinery you can use to make that happen.

Pre-Roll Machine Accessories

Aside from having extra trays to help with your production, you will also have the option to add accessories to your pre-roll cone packing machines in order to meet specific needs.

One of the best accessories is a Metering Tray . A metering tray ensures that every pre-roll cone/tubes get the exact amount of cannabis flower that you intend. It also ensures that all your pre-rolls will be consistent. Every state is going to have their own regulations for how precise you need to be with the weight of your products, so this is a great way to also ensure that you are staying in compliance.

The only downside to a metering tray attachment is that it slows down production. This is enough reason for many producers to continue to just eyeball the process and live with giving the consumer a little more than the exact amount. Considering that each pre-roll should be weighed before it leaves the facility, compliance becomes less of an issue; however, if you eyeball wrong, that time you saved by not using a metering tray gets negated, as you will need to redo the pre-rolls.

Another helpful accessory is the Work In Progress Tray . Nothing fancy here, just an easy way to store your pre-rolls in an upright position until they can be tamped, folded, and weighed. They are also a great way to hold infused pre-rolls that have concentrate painted on the outside. It keeps these sticky joints separate and clean. What’s also cool about this product is that it’s designed to be versatile. One side holds cones, and the other side fits hemp wraps.

3 Ways to Seal a Pre-Roll

- Twist

- Dutch Crown

- Fill and Fold Machine

Automated Pre-Roll Machines

When you hear “automated,” you might think these machines require zero human supervision. This is not the case. Automated machinery may do the heavy lifting of your project, but they still require 1 or 2 humans to keep tabs on it while it’s working. If the machine is doing something wrong, it’s not going to know to stop. A person needs to be there to stop the machine and make adjustments as needed.

You also need to make sure that the material you are putting through the machine is up to specifications. Automated machinery works the best when all the particles running through the machine are uniform in size. This was actually discovered by pharmaceutical companies, as they tested the efficiency of their automated machinery. In other words, as well as being ideal for creating a pre-roll that smokes well, investing in a quality grinder for your flower is a powerful tool to help your automation run smoothly. We recommend your particle size be around 2mm. Chunkier sizes (3mm to 4mm) will start to cause issues.

Also, like the standard machinery, attention needs to be paid to the moisture content of the flower material. If the flower is too moist or sticky with resin, it is going to gunk up the machinery—slowing down production and requiring more frequent cleaning. This is why many producers decide to dry out their material a little more than usual when they make pre-rolls. You still have to avoid over-drying, but the moisture content needs to be around 10-12%.

The temperature of the room is also going to play a big part in how easily the material moves through the machinery. The combination of people and machines can make the production floor get warm quickly, and, once it starts to get warm, the flower material will start getting sticky and slowing down your production. In short, before you can move into pre-roll automation, you need to make sure you can control the temperature and humidity in your production facility.

Pros and Cons of Automated Machinery

There are definitely some solid advantages to using automated pre-roll machines. You’ll be able to get exportable production data, the labor costs for each pre-roll drops considerably, there is extreme uniformity in your pre-rolls, and there are less humans touching the product—avoiding contamination and plant degradation. These machines can also be a part of a larger pre-roll automation system, as they fit seamlessly with the automated packaging machines.

The drawbacks to automated pre-roll packing machines include: expensive set-up costs, dependency on a machine (how will you make pre-rolls if it needs a repair?), you can’t process sticky flower easily, you must have a consistent grind (use an industrial grinder), and you won’t be as flexible when it comes to the size and shape of the cones you want to fill.

When Does Automation Make Sense

Automation machines are expensive and require you to process flower a specific way, so they aren’t going to be the perfect solution for every situation. Incorporating automation into your production is going to depend on your production goals and/or manufacturing abilities.

If you are looking to pump out more than 50 thousand a year, automation is definitely something you should consider. It makes sense from a financial perspective and will give you much needed consistency; however, if you are looking to stay on the premium track and give your customers a more craft experience, other machinery is going to be your best bet.

The role of any piece of machinery is to compliment what you are already doing. So, if you have any questions about which machine would work best for you, be sure to give us a call. We’re happy to go over all your options.

Manufacturing Infused Pre-Rolls

Like the pre-roll production process, you will have the option to incorporate automation into your infusion process; however, also similar to pre-rolls, automation will limit your options for how you can infuse your pre-rolls.

If you choose to infuse your pre-rolls by hand, there aren’t restrictions on what type of concentrates you can use. You just need to have the time to make it work. For example, the most popular type of infused pre-rolls are hand-painted on the outside with distillate and then covered in kief, and more premium producers will roll a line of rosin into the center of the joint (hash hole).

With all these hand-crafted options, you will have the chance to create unique products that are sure to grab the attention of the customer; however, if you want to produce infused pre-rolls in mass, you really can’t beat an automated pre-roll infusing machine.

The process starts by getting the pre-roll infusion machine loaded with pre-rolls and concentrate. The pre-rolls are arranged inside a circular wheel, and the liquid concentrate sits in a specially designed reservoir to make sure it stays at the optimal temperature.

This automated technology comes with a touch screen, which allows you to not only control the exact amount of concentrate that gets infused, but the exact location as well. You can set the desired length of the infusion, as well as where it starts and stops. What's also convenient is that the machine has been designed to be easily run and calibrated by a single operator.

The result is an infused pre-roll product that is consistent in quality and can be produced in mass. If this sounds like something you’d want to get more details about, be sure to check out our blog on pre-roll production, or just reach out to one of our Pre-Roll Experts.

Packaging

Lastly, you are going to package your pre-rolls so they can be shipped at sold at retail establishments. To take a deep dive into your packaging options, be sure to check out blog that is completely dedicated to packaging, but here is a quick overview of what you’ll need to think about.

Final Inspection

Before you send your product away, it is crucial to give it a thorough look over. Not only do you want to make sure everything looks right, but you also want to make sure it meets compliance regulations. After spending all that time, the last thing you want to happen is for your customers to get a damaged product or for the shops not to be able to sell the pre-rolls because they are not compliant with the law.

The first thing you want to do is weigh each pre-roll to make sure they are accurate. Most states allow you to be roughly 5% off from what it says on the package. That being said, be sure to take into consideration the weight of the cone before weighing the pre-roll. All you have to do is tare the scale with an empty cone before you start weighing.

Next you want to make sure everything looks okay in terms of the quality of the pre-roll. For example, there are a few things that can cause the paper to tear on the outside of the pre-roll. A stem could’ve found its way into the cone, or the cone might have been too tightly packed/tamped. Maybe the cone is just falling apart, wasn’t twisted properly, or has an uneven gum line. Some of these problems can be fixed, but some just need to be not packaged.

A great pre-roll should look clean and feel like a ripe tomato when you lightly squeeze it. In other words, there should be some give, but it should spring right back into place. That means the flower is perfect and the pre-roll has been beautifully packed. It will produce a wonderful smoking experience for your customers.

Pro Tip: Be sure to invest in quality cones/tubes/papers. Here at Custom Cones USA, we pride ourselves on offering top quality products that are sure to impress your production team as well as your customers. Don’t let a bad paper ruin all your hard work.

Containers & Wraps

The packaging and branding you choose to put on your pre-roll is more important than you think. The pre-roll market is big, and the only thing that is going to separate you from the competition on the shelf is your packaging and branding.

We offer a wide variety of packaging options, and we can even help you make something custom that will be sure to attract customers. You just have to figure out what you want your packaging to “say” about your company.

Do you want your brand to feel affordable or luxurious? Do you want your packaging to say that you care about the environment or that children won’t be able to get through the child-resistant features? Is it for a single use, or do you want to create a multi-pack for the extra loyal consumer?

Once you get an idea of what you want, you can start going through the different types of tubes (Pop Tops, Glass, Super Seals, PET Tubes, etc.) and multi-packs (Push Packs, Cigarette Boxes, Tins, and Plastic) to find the perfect one for your brand. We even have customizable pre-roll displays (Gravity and POP styles) that you can give to shops to help make an impact!

Lastly, if you need help with your branding and graphic design, we offer branding and wrapping services to make sure everything looks exactly the way you want. And, at the end of the day, that is what we strive to do at Custom Cones USA. We want to use our expertise to make your vision come to life. So, let’s get started!

Here you will find everything you need to get started producing the best pre-rolls. Each step is broken down so you know exactly what you’ll need to get going.