PPE in Cannabis and Pre-Roll Production

Posted by Custom Cones USA on Mar 11th 2025

Whether a cannabis consumer in the market or a producer in the industry, human safety must come first.

With an ever-expanding U.S. and global market – through individual states and countries decriminalizing cannabis for medicinal use, recreational use or both, as well as growth in emerging markets – cannabis producers, specifically pre-roll producers, should consider a PPE program to combat hazards in the workplace and for the protection of their production team.

Today, we look at the current state of the cannabis industry through the lens of safety and the use of PPE, or personal protective equipment, in pre-roll production. We’ll define hazards in cannabis and pre-roll production, PPE requirements for specific roles in the production process, essential PPE equipment required for worker safety and facility safety protocols, as well as implementation, training, and regulatory compliance.

No matter the cannabis product being produced, nor the minimum requirements set forth by regulators, strong investment in employee safety through personal protection equipment at every step of production is an obligation for a cannabis brand to reduce environmental hazards in facilities for workers from cultivators to processors.

Our Pre-Roll Experts at Custom Cones USA take pride in the high standards of testing and compliance set forth in our pre-roll products, as well as the safety of producers, meeting and exceeding the requirements for compliance of Health Canada and California Phase III regulations.

For the safety of their employees, pre-roll producers should invest in PPE programs to not only ensure safety in their facilities, but to also build a reputation of trust among industry professionals and consumers alike.

The industry has the opportunity to set high-standards and represent what employee safety really means, and for those who employ comprehensive PPE programs, the benefits will greatly outweigh the lift of implementation.

This is of significant importance following the passing of a Massachusetts cannabis employee who in 2022, suffered an asthma attack in a pre-roll manufacturing facility operated by a top national brand. An investigation conducted by the Massachusetts Department of Public Health and the Occupational Safety and Health Administration (OSHA) confirmed this as the first known occupational asthma fatality in the U.S. cannabis workforce.

Table of Contents

- The Cannabis Industry at a Glance

- Justifying PPE Programs in Pre-Roll Production

- Mandated OSHA Hierarchy of Exposure Control

- Biological Hazards

- Chemical Hazards

- Physical Hazards

- Essential PPE for Pre-Roll Production

- Roll Specific Hazard Prevention

- Hazard Mitigation and Regulatory Compliance

- Commitment to Safe Pre-Roll Production

The Cannabis Industry at a Glance

In the U.S. alone, the cannabis industry is supported by more than 440,000 workers, from budtenders to pre-roll manufacturers. In Canada that number sits just below 88,000. Cannabis sales tracked in 13 states by analytics provider Headset showed the U.S 2024 amassed $20.6 billion in cannabis sales, while the 4 tracked provinces in Canada pulled in $3.95 billion in revenue.

Pre-roll sales in the U.S. totaled $3 billion and $1.3 billion (CAD) in Canada, with the U.S. moving 316.8 million units compared to Canada’s 69.8 million.

The scale of the industry is growing at a rapid pace, with the first U.S. recreational markets emerging in 2012 and Canada’s national legalization arriving in 2018. Medicinal cannabis in the States dates back to 1996 in California the passage of the Compassionate Use Act, while Uruguay was the first to pioneer recreational cannabis, legalizing the production, sale and consumption nationally in 2013.

With recreational cannabis now legal in 24 states and nationally in Canada and other countries across the globe, protecting the growing industry workforce is not just important for continued production of cannabis products, it is a moral obligation, with responsibility coming from the top.

Justifying PPE Programs in Pre-Roll Production

Safety challenges arise at every stage in cannabis production, often dating back to illicit grow rooms with no windows and poor ventilation to present day facilities. Most guidelines for handling cannabis stem from protocols employed by law enforcement to protect officers during raids, but these guidelines don’t encompass the entire process of cannabis cultivation and product production.

Cannabis producers are subject to the same Occupational Safety and Health Administration (OSHA) regulations that apply to other American industries, including that employers must provide employees with a workplace free from identifiable hazards that have the potentiality to cause serious harm or even death to workers. These standards are set by the OSHA General Duty Clause - Section 5 (a)(1) of the Occupational Safety and Health Act (OSHA) 1970.

Regulations governing workplace safety vary from state to state, but cannabis as an agricultural crop is also governed by current federal safety regulations for agricultural operations, which have been extensively developed over time.

As with any new market, oversight and regulatory compliance develop over time. And while enforcement of workplace violations of employee protections may not be at the required levels for industry-wide safety assurance at this stage, that won’t last forever. Employing strict PPE measures and procedures as soon as possible is not only an obligation all producers have to their workers, but is also getting ahead of regulations almost certainly on their way.

Not only does PPE protect the pre-roll manufacturers throughout the entire process of production, it also protects and ensures quality and integrity of the cannabis itself. PPE is an overall sound move for any pre-roll business. Or as the Washington State Department of Labor & Industries puts it: “Preventive efforts make good business sense when you begin to consider the possible costs associated with a tragic accident."

The most established, profitable pre-roll producers can be hit with major financial judgements such as fines and lawsuits for failing to protect workers in their facilities. No matter if employees show minor symptoms or a major complication, preventative measures and proper protection greatly reduce the chances of exposure, reaction and injury.

Mandated OSHA Hierarchy of Exposure Control

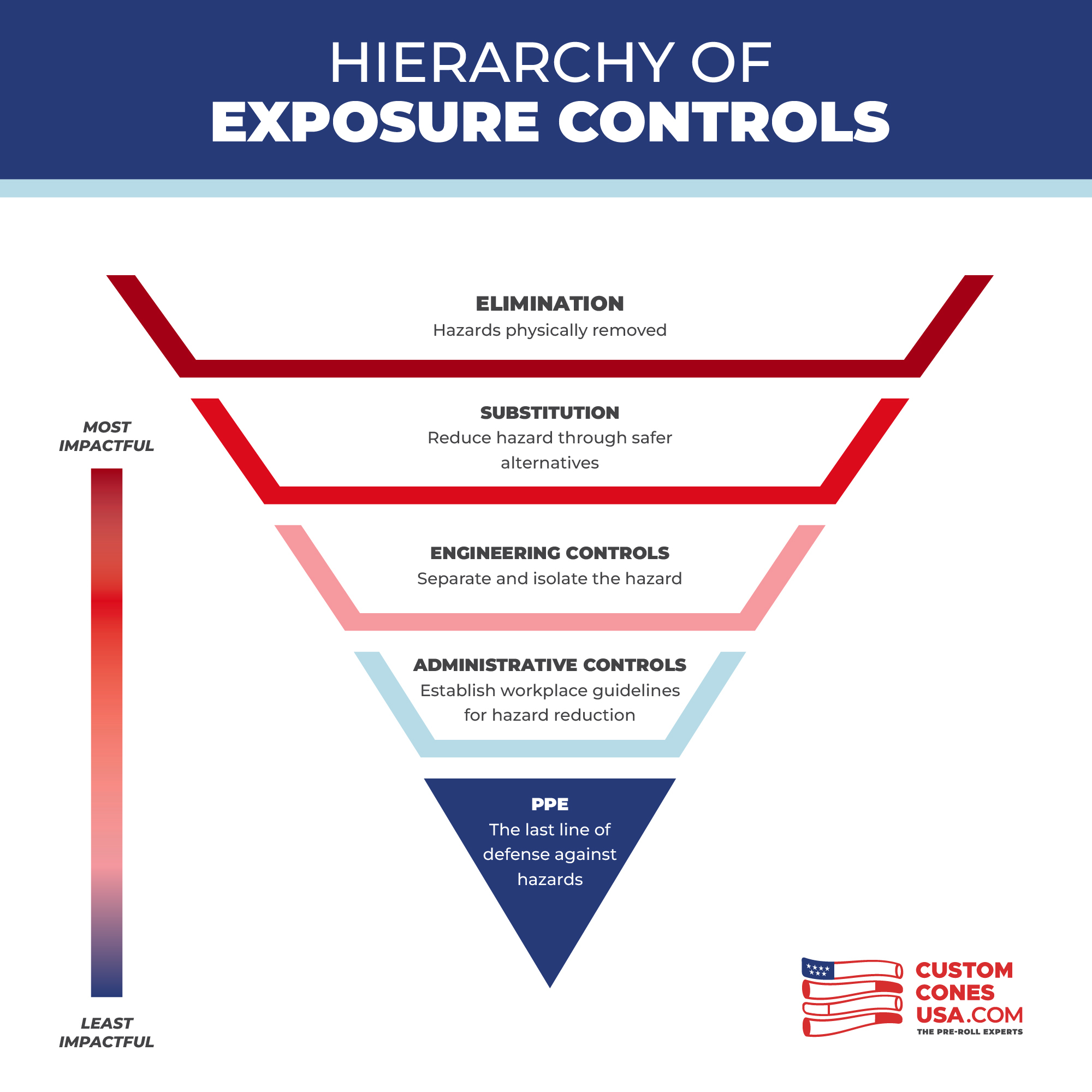

Three primary hazards and exposures are present in pre-roll and overall cannabis production from seed-to-sale: chemical, biological and physical. While PPE programs are a must, it is only the last line of defense against these hazards. The OSHA-mandated Hierarchy of Exposure Controls defines the most and least effective control measures to protect against workplace hazards, eliminating risks altogether or substituting lower-risk alternatives first and foremost.

The most effective aversion to hazard is elimination of the hazard from the specific process, or by the substitution of a less hazardous solution to a process over a hazardous one. These implementations provide the most effective protection for workers and are optimized when implemented in design and development.

Engineering controls are simply a change in processes, tools, equipment and even facilities for hazard and risk reduction. By removing the hazard at its source before coming in contact with workers, individuals are removed from the hazard through controls of process, isolated operations, proper ventilation to reduce the severity of exposures to workplace hazards.

By changing the way people work through administrative controls, hazard reduction measures can be implemented to reduce employee exposures to risk including but not limited to emergency protocols, proper education and training, and employee support measures such as breaks, workforce rotations, health evaluations and proper upkeep and cleaning of equipment and facilities.

And finally, the last line of defense, PPE, or personal protective equipment, used in tandem with other controls to protect workers from hazardous exposure .

Biological Hazards

Referring to exposure to allergens and sensitizers, materials such as the cannabis plant that cause a reaction in normal tissue after repeated exposure, as well as mold, are what is known as "biological hazards." Symptoms and reactions occur in both the dermis (skin) and respiratory system, with adverse physical reactions including irritation, hives, dermatitis, congestion, inflammation, and wheezing.

Mold is a serious hazard as marijuana cultivation requires high levels of humidity, often as high as 70%, and the combination of humidity and organic plant matter promotes mold growth unless properly managed. The presence of mold spores in the air can cause respiratory infection and amplified respiratory symptoms from existing conditions such as asthma.

To mitigate water intrusion and mold in production facilities, moisture control is key in mold control from structures to surfaces. Testing for mold and fungus periodically is important. But implementing respiratory, eye and skin protections, as well as enhanced body protections when necessary, will protect production employee from mold, allergens and sensitizers alike.

Handling of cannabis plants and byproducts with the hands and skin protected greatly reduce the possibility of allergic reaction, and when paired with proper ventilation, exhaust control, personal respiratory protections and effective training, a safe environment can be cultivated for employees and plants alike. Managing engineering controls through proper ventilation, while limiting exposure through PPE such as masks and gloves, will reduce the likelihood of allergic reactions, hypersensitivity, and even anaphylaxis.

Ways to Avoid Biological Hazards

- Implement strong engineering controls around facility ventilation.

- Maintaining a clean environment equipped with moisture control.

- Conduct a PPE assessment to determine respiratory, skin and eye protection.

- Conduct mold sampling.

- Worker rotation, training and scheduling to avoid prolonged exposure.

Chemical Hazards

Preventing exposure to chemicals and gasses is extremely important in any industry, and with pre-roll production centering around the primary feature of a pre-roll, cannabis flower, managing the health of plants introduces chemical hazards throughout the cultivation, processing and manufacturing stages.

Unlike biological hazards, chemicals hazards are physically introduced to the production process or created as a byproduct in production. Fertilizer and other nutrients given to plants for optimal growth present risks for exposure. Additionally, exposure to corrosive compounds in the mixing process can damage bodily tissue, creating irritation and burning to the point of blistering. Breathing these corrosive vapers can also irritate the throat, nose and lungs, potentially causing serious lung damage.

As most corrosives are either a bass or an acid, common acidic encounters include phosphoric acid, nitric acid, hydrofluoric acids, chromic acid and more. Common bases in pre-roll production that may cause hazard to employees include sodium hydroxide and ammonium hydroxide.

Risks of chemical exposure increase with the introduction of pesticides, insecticides and fungicides.

Pesticides like neem oil and pyrethrins have low volatility and are non-persistent, meaning they breakdown quickly rather than lingering and depredate quickly from exposure to air, light, and microbials. But while a reduced risk compared to other chemical hazards, risks of dermal and respiratory toxicity for employees applying these pesticides do exist and could be detrimental to worker health.

Chemicals found in cleaning products and disinfectants can also present risks as the ingredients could range from mild irritant to corrosive chemical. Bleach for example is a common cleaning agent, but exposure from spills and splashes can cause skin, eye and respiratory problems. With the range of cleaning products on the market, choosing the safest cleaner and disinfectant that gets the job done will benefit employees and employers in the long run.

Mixing of certain chemicals like bleach and ammonia can create terribly dangerous gasses that can be toxic to humans. Understanding proper usage, storage and PPE requirements through effective education, information and training will reduce the odds of accidents.

Air quality also presents the opportunity for chemical exposure, solidifying the importance of proper ventilation. Carbon monoxide from exhaust can permeate a workspace and carbon dioxide used to increase plant growth, flash freeze, or for the production of concentrates can pose lethal issues if not prevented and managed.

Ways to Avoid Chemical Hazards

- Strong Engineering and administrative controls including built into facilities and production processes.

- Incorporate CO2 monitors to detect elevated levels.

- Consider using tools that run on electricity or compressed air to avoid carbon monoxide exhaust, avoiding combustion powered tools indoors while. Installing CO monitor will help detect this colorless, odorless, and toxic gas.

- Ensure HVAC systems are in place, work effectively, and are capable of managing ventilation for the size of the facility.

- Incorporate respiratory, hand, eye and body PPE that are chemical resistant.

- Make sure chemicals are properly stored and labeled, avoid mixing or off-label uses, ensuring proper disposal as well.

- Ensure proper dilution of cleaning products and a dedicated area where solutions can be prepped can cleaned up.

- Substitute harmful chemicals with safer alternatives when possible, accounting for any damage upon arrival.

- Make sure corrosives are stored in the correct container and on proper shelving, storing them on low, non-metal shelves.

Physical Hazards

Direct exposure to hazardous conditions in production environments add bodily injury and physical harm to the risks of cannabis production. And since physical hazards are primarily encountered within the confines of the workspace, the environment created in production facilities greatly correlates with risks to employee’s physical well-being.

Physical risks are everywhere as the sheer fact of being present at a facility brings inherent risk, no matter the preventative measures, though a properly executed hierarchy of safety controls and processes overwhelmingly reduces the risk of injury. Slipping, tripping and falling at ground level or at heights presents risk, as does noise and UV light, injury of the body through movement, machinery, compressed gas, electricity, combustible liquids and workplace violence. Even the physical space in a facility can present physical hazards through the containment and accumulation of harmful aerosols.

Extraction of cannabis concentrates, with the presence of combustibles and risk of fire hazard, is an especially dangerous process if not managed properly.

Though all hazard categories present the possibility of physical harm, physical hazards can be mitigated through engineering and administrative controls, providing low-risk environments and effective training to lower risks of physical and mental distress among pre-roll producers. Proper storage and usage of production supplies, as well as the oversight of facility and machine operations, reduce dangerous situations that can irritate, injure or even kill an employee. Hazard reduction and employee safety must be paramount in any cannabis cultivation and manufacturing facility.

Ways to Avoid Physical Hazards

- Reduce the use of flammable chemicals and liquids used in production for non-flammable alternatives. Flammables need to be stored properly and are best handled under a chemical fume hood.

- Ensure safety release valves are intact on compressed gas containers.

- Ensure first-aid plans, medical supplies, and access to medical treatment is known and accessible.

- Train employees on how to avoid injury in their work, incorporating devices such as support belts or slip-resistant shoes to avoid strain and accidents during work shifts, promoting ergonomic solutions where applicable.

- Establish a zero-tolerance policy towards workplace violence in production facilities, covering all individuals associated with production, encouraging reporting and accountability.

- Ensure floors, passageways, rooms and entry ways are clean, level and safe. These areas should be cleaned, maintained and free of hazards such as missing tiles, protruding nails, or even snow outdoors.

- When working at heights, strap in, ensure railings are in place and surfaces are void of liquids, grease or oils. When ladders are in use, maintain three-point contact with the ladder.

- Regarding electricity, make sure surge protection is in place, bond and ground, avoid wet locations, and eliminate obstacles created by wiring.

- To protect against excessive noise, avoid amplification, reverberation and propagation of noise, servicing machinery regularly to reduce vibrations.

Essential PPE for Pre-Roll Production

Personal protective equipment simply refers to the protective clothing and bodywear that protects the wearer from bodily injury. As this is the last line of defense against exposure to harmful situations, the consistent use of PPE adds a layer of separation from the environment.

Elimination, substitution, engineering controls and administrative controls are the most effective preventative measure cannabis pre-roll producers can take, but the value of PPE is astronomical in reducing exposure whether brief or prolonged.

PPE for the Body

- Protective clothing: Including pants, long sleeves, coveralls, and garments resistant to heat, UV, chemicals, etc.

- Disposable proactive suits: Variations in materials correlates to the task being performed. For example, Dupont carries 3 fabrics for their protective garments: ProShield, Tyvek, and Tychem. The ProShield fabric protects against particles for general work, Tyvekmaterial adds resistance to oils and resins as well as cleaning chemicals,while the Tychem fabric defends against pesticides and extraction solvents.

- Aprons, lab coats and frocks: Adding a protective layer between body and processing area.

- Safety harnesses: When working at heights, mitigating fall risks through harnesses is a must.

PPE for the Hands

- Resistant gloves: Such as cut-, chemical-, heat- and water-resistant gloves

- Nitrile gloves: Prevent irritation and dermatitis caused by chemicals, solvents and oils. Latex gloves are not recommended as they can be a source of irritation themselves.

- Full body suits with built in gloves: For added hand, wrist and arm protection, disposable body suits with attached gloves eliminate direct exposure.

- Vinyl gloves: Valuable as a cost-effective option for low-risk tasks, medical grade disposable gloves should be at 2.5 AQL or more (acceptable quality level).

PPE for the Head, Face, and Eyes

- Face shields: Provide full facial coverage against splashes and airborne particles.

- Safety glasses or goggles: Including Impact, UV and fog resistant options. Prescription glasses, side shields and protective lenses must meet the standards of safety goggles.

- Bouffants, beard covers and hoods: Protect hair from contaminating product while shielding hair from buildup of airborne particles.

- Earplugs and earmuffs: Noise induced hearing loss is avoided by keeping noise below 85 decibels.

PPE for the Respiratory System

- NIOSH certified respirators: Specific respirators that are certified by the National Institute for Occupational Safety.

- Half and full-face respirators: Half-face respirators carry an APF of 10 while full face respirators carry an APF of around 1,000.

- APF respirators: The likes of the classic N95 mask, FFR classifies masks as non-resistant to oil (N), somewhat resistant to oil (N), and strongly resistant to oil (P). They are rated at 95, 99, and 100, removing 95%, 99%, and 99.97% of airborne particles respectively.

- FFG: Classic 3-layer disposable facemasks for general use.

- Air-purifying respirators: Equipped with cartridges or filters to better filter particulates, chemicals and gases.

- Self-contained breathing apparatus: Similar to the masks worn by firefighters, SCBA’s incorporate air canisters for clean breathing.

PPE for the Feet

- Boots and protective shoes: Strong, protective footwear including steel-toed, slip resistant, and chemical resistant.

- Shoe and boot covers: Protects against product contamination as well as protection for the user against hazardous particles.

- Full body suits with built in shoe covers: Avoids gaps between PPE offering full coverage.

Roll Specific Hazard Assessment

Cultivator: Tasked with planting, nurturing, protecting, maintain, harvesting and drying of the cannabis. Potential hazards include exposure to mold, allergens and sensitizers, pesticides and fungicides, as well as poorly maintained facilities.

Trimmer: Responsible for trimming plants and preparing the flower for the next stage of production or packaging. Hazards resemble that of cultivators but are elevated due to the prolonged contact with the plant.

Extraction Producer: Producers of cannabis concentrates, exposed to hazards from machinery, air quality, allergens, noise, chemicals like solvents, and flammable chemicals. Extraction is a well-known process where safety concerns are high and industry wide.

Concentrate Applicator: Responsible for producing products with cannabis concentrates including infused pre-rolls, edibles, and beverages. Occupational hazards are less prominent, but burns, noise and chemical complications can arise.

Leb Tech: In charge of testing cannabis and products for quality and compliance, lab techs risk irritation from cannabis exposure as well as solvents.

Maintenance: Upkeep of facilities puts maintenance technicians in similar hazardous situations as other positions in the operation, but with the nature of the roll, hazards such as heights and electricity are increased.

Hazard Mitigation and Regulatory Compliance

A safe facility should be the goal of cannabis and pre-roll producers alike, but in order to implement the measures to ensure safety, a PPE plan must be informed through a PPE assessment that includes:

- Assessing the workplace for biological, chemical and physical hazards;

- Implementing engineering and administrative controls to mitigate hazards before the work starts as they are the most effective measures in reducing hazards;

- Defining the required PPE to protect employees from hazards that cannot be eliminated by engineering or administrative controls;

- Properly communicating the reasoning and importance for adhering to the measures of the PPE plan being implemented through education, training, and documentation;

- Defining the necessary emergency protocols required to contain and manage incidents as they happen in an emergency action plan. These will include roles and responsibilities, evacuation plans including routes and exits, and important locations for emergency equipment and meeting locations; and

- Understanding federal regulations to stay compliant with OSHA, EPA, NFPA, WPS, and industry standards and guidelines, as well as state-specific and local regulations, such as building and facility codes, licensing, and reporting obligations.

Ensuring Safe Pre-Roll Production

- Conducting a PPE assessment for production facilities is the first step towards hazard reduction. By understanding the hazards in your facilities, you can employ OSHA’s mandated hierarchy of exposure controls, understanding that elimination and substitution, followed by engineering and administrative controls are the most effective measures in risk reduction.

- After these measures have been planned or implemented, the necessary PPE can be identified by the remaining risks associated with roles, processes, and areas of the production facility.

- Custom Cones USA has been a leader in the pre-roll industry since 2017 and employee and consumer safety is our number one priority. Our refined white, natural brown and organic hemp rolling papers are produced in ISO certified facilities in France, environmentally friendly and FSC Certified, and have been tested for heavy metals, pesticides, and microbials. Our hemp and hybrid hempblunt wraps, made from 100% European hemp, are also tested to the same high standards as our rolling paper.

- Our manufacturing and warehouse facilities employ the hierarchy of exposure controls including a broad range of PPE to ensure safety for our workforce.

With an ever-expanding U.S. and global market – through individual states and countries decriminalizing cannabis for medicinal use, recreational use or both, as well as growth in emerging markets – cannabis producers, specifically pre-roll producers, should consider a PPE program to combat hazards in the workplace and for the protection of their production team.