When to Automate Your Pre-Roll Production Process

Posted by Custom Cones USA on Jan 5th 2024

With your pre-roll product line launched, packaged beautifully and beginning to build a strong customer base, it’s time to start thinking about meeting demand, and that means it might be time to start thinking about automating your production line.

But how do you know when the time is right? What are the pros and cons of automating? And what do you need to know before you go all-in on buying an automated pre-roll filling machine?

Thankfully, the Pre-Roll Experts are here to help.

When Should You Automate Your Pre-Roll Production Line

For most producer/processors, deciding when to buy an automated pre-roll filling machine is a math problem: what is the total number of pre-rolls you are producing each month and how much does that cost in labor verses getting a machine to do it?

Automated pre-roll filling machines can make between 1,000-3,000 pre-rolls per hour. So when it comes to buying an automated machine, the math for most companies begins to make sense at more than 50,000 pre-rolls a month, which is pretty rarified air for a producer; less than 10% of companies make that many.

However, there is more to think about than just the upfront cost.

One consideration is the type of flower and/or oils you plan on packing into your pre-rolls. If your flower is too sticky, automation may not work as well as other cone-filling methods and machines. Additionally, automated machinery works best with consistent inputs and if you are planning on making pre-rolls containing multiple of strains of cannabis – or if your cannabis source is not consistent – then automation could increase your turnover time between production runs and ultimately slow you down.

Automated filling machines are fast once they get up and running, but it takes some time to change the settings for a different pre-roll. Extended down time can eat into profits, so it’s ideal to run these machines when you only need to adjust for 1-2 different SKUs in a day. If you are trying to manufacture 3-5 different sizes of pre-rolls, with multiple strains per week, you might be best using table top pre-roll machines instead of making the jump to full automation. You can create thousands of pre-rolls per shift with just 1 machine, so by scaling up to multiple table top machines, you can vastly expand your production capabilities without automation.

One final thing to take into consideration is your product line itself: what type of pre-rolls do you make and sell? Again, automated filling machines work best when all things are consistent. If you are planning on a wide range of SKUs, the turnover time from pre-roll to pre-roll might not be worth the purchase. For example, if you are making hemp wrap blunts of various shapes and sizes, standard pre-rolled cones, as well as premium tipped products like glass or wood tipped joints or blunts, there is no way to automate all these lines without investing upwards of a million dollars on multiple automated pre-roll machines.

Additionally, not all automated machines can fill both pre-roll cones and pre-roll tubes, so be sure to take that into consideration when looking to move to an automated production cycle.

What are the pros and cons of automated pre-roll filling machines?

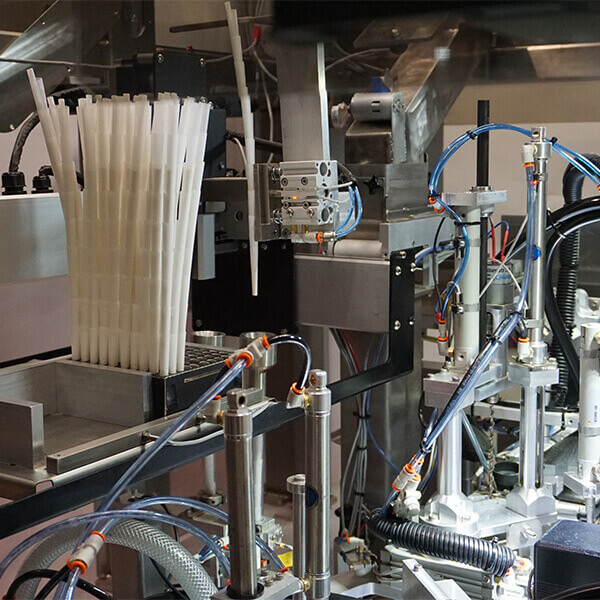

Fully automated pre-roll machines are the ideal solution for large brands looking for a more hands-off approach for their pre-roll production process. Automated pre-roll machines can take boxes of cones, ground cannabis and automatically fill, pack, tamp, twist, cut off any excess paper and even weigh the final joint, providing a level of consistency and labor cost unmatched by tabletop pre-roll manufacturing methods.

Additionally, pre-roll machines like this can autonomously run for hours with limited human interaction, which can create huge labor savings and free up employees to package the pre-rolls or finish other projects. However, these machines must be continuously monitored and often require slight adjustments throughout the day to keep things running smoothly. If a manufacturer tells you their machine can run with no human interaction, they are just not being honest.

But there are downsides to automated pre-roll filling machines, too. First, the cost can often be too high for smaller businesses. And as we’ve noted, they can also be incredibly persnickety. Machines are designed to operate in a uniform and repeatable fashion, but as an input, cannabis is anything but uniform. Automated pre-roll machines are simply not as flexible and forgiving as tabletop pre-roll machines like the King Kone pre-roll machine or the Fill N' Fold pre-roll filling machine.

Different strains – and even different harvest of the same strain – vary greatly in stickiness and density and the changeover from one strain to another can take time because recalibration may be needed and the changeover and cleaning, taking your pre-roll production offline during the process often for longer than a tabletop machine would be down.

There is also often a higher level of training necessary to operate these machines, so it is important to have a dedicated employee or two. Many automated machines are complex and require workers with machine operation experience. Some machines may even require someone with some engineering background. By dedicating employees, you can capitalize on expertise. If there is a lot of turnover on your production team, the constant retraining of employees to handle automated filling machines can cause significant downtime that will cost time and money and lengthen your ROI on the machine.

What other things should I consider to do automation right?

Still with us? Great. Then your company is probably a good candidate for upgrading to automated pre-roll filling machines. But even after you buy, there are still some important things to consider to make sure your pre-roll production process is smooth. Many automated pre-roll machines, for example, require that the cannabis material be more finely ground, drier, and have a consistent particle size to function properly.

Automated pre-roll machines require a consistent grind size

As noted, consistency is vitally important to painless automated production, especially particle size. The cannabis needs to be able to flow smoothly and consistently through the machine. To ensure this, it’s important to have a good industrial cannabis grinder and sifter that will ensure your cannabis is ground to the same size and cleaned of things that can get in the way, like stems and other jagged parts that can slow the flow of particles or rip the paper or your pre-roll cones.

Most automated machines, like the AuraX and AuraOne, need a particle size of between 1-5mm in order to keep things moving. The Aphehex machine needs are even more specific, recommending a particle size of 2.5mm sifted through a 1/8-inch screen for optimal performance.

Automated pre-roll machines require consistent water activity and humidity

Like particle size, it is important to be certain that the moisture level of your cannabis input is consistent. Inputs that are too moist or sticky will cause everything to slow down and/or not work properly. For large operations, it’s important to keep your cannabis in humidity-controlled environments to maintain a consistency of inputs. The most advanced automated pre-roll productions measure both moisture content, as well as water activity – plotting these figures on a graph and noting which strains perform the best given these data points.

Automated pre-roll machines need a consistent, cool temperature

Like moisture content and humidity, room temperature will affect your cannabis. For example, the resin in the cannabis will become sticky and cause issues if the room where you are operating your automated machinery is too warm. It is always recommended that you install and operate your automated pre-roll machine in a climate-controlled room, both for humidity and temperature.

Automated pre-roll machines need trained operators

While automated pre-roll filling machines don’t take as much labor to operate as tabletop machines, the work is more nuanced and takes more training to achieve the speed and consistency that make automated machines worthwhile. It makes the most sense to train a dedicated employee or two to run these machines to keep things running smoothly and producing high numbers of pre-rolls day after day as, again, different strains may need different grinds to work.

Automated pre-roll machines require high quality pre-rolled cones

Finally, don’t skimp on your pre-roll cones and tubes. Make sure you have cones that are also consistent in their quality and will work in the automation process. The machine isn’t going to realize if there are slight issues in the opening diameter or size of the cone and adjust it to make it work. Inconsistent, flimsy and other low-quality cones just aren’t going to be good enough to work with automated machinery, so make sure your pre-roll cone provider is as dedicated to quality as you are.

Final Thoughts

Automated pre-roll filling machines are a big step for any cannabis business, so it’s important to make sure it’s the right decision and the right time for your company. Always work with an expert and be sure your pre-roll supplier has your best interests in mind and isn’t just trying to sell you an expensive machine you don’t need.

With your pre-roll product line launched, packaged beautifully and beginning to build and strong customer base, it’s time to start thinking about meeting demand, and that means it might be time to start thinking about automating your production line.