Water Activity and Moisture Content in Cannabis and Pre-Rolls

Posted by Custom Cones USA on May 28th 2025

If you’re not paying attention to the water activity and the moisture content of your flower and your pre-rolls, you could be costing your company money and sending your customers to a fresher, more flavorful and more potent competitor.

But what exactly are moisture content and water activity? What’s the difference between them? And what do each of them mean for the quality, compliance, flavor and harshness of your pre-rolls, not to mention your bottom line?

A new, first-of-its-kind study sponsored by Custom Cones USA and DaySavers called “The Science of Smokeability” is providing exciting new insights on how water activity and moisture content are not only affecting your cannabinoid and terpene levels, but the user experience itself. We’re excited to share the results and what they can mean for your pre-roll production.

So let’s take a deeper look at the difference between water activity and moisture content, how they both apply to cannabis and their effects on producing high-quality pre-rolls at scale.

Water Activity vs Moisture Content: What’s the Difference?

While related, water activity and moisture content mean different things and serve distinct purposes in ensuring product safety, quality, and shelf-life. Let’s start by defining each term and what it means for cannabis.

Moisture content refers to the total amount of water present in a cannabis sample, expressed as a percentage of its total weight. It helps determine the "dry weight" of the product and in cannabis is used in part to help calculate potency and cannabinoid and terpene percentages.

Cannabis flower typically has 6–15% moisture content, though a lower moisture content around 9% is best for producers who use automated pre-roll filling machines.

Water activity, on the other hand, measures the availability of what is called "free water" in the cannabis sample.

It can influence microbial growth, stability and combustion. It is also a key contributor of product performance and customer satisfaction. It is defined as the ratio of water vapor pressure above a substance (p) to that of pure water (pₛ) at the same temperature.

aW = p/ pₛ

Water vapor pressure, as an aside, is the pressure exerted by water vapor molecules when water is in equilibrium with its vapor in a closed system at a given temperature. Basically, it is a measure of how much water has turned to gas and is pushing against the walls of a container or air above the liquid. The warmer it gets, the higher the vapor pressure. Water boils when the pressure matches the air pressure outside the container.

Water activity is expressed as a decimal value between 0 and 1. It also predicts susceptibility to mold, mildew, and bacterial contamination and helps gauge product stability and shelf-life.

For cannabis, the ideal water activity range is 0.55–0.65 aW. Values above 0.65 aW increase contamination risk by providing a potential breeding ground for molds, while values below 0.55 aW can lead to brittleness and terpene loss.

Most states require cannabis products be tested for both as part of their laboratory testing requirements.

Why Water Activity and Moisture Content Matter

Besides the safety concerns, proper water activity and moisture content are both essential for ensuring product quality. For example, proper control of water activity ensures a longer shelf-life by minimizing degradation risks. Moisture content can affect weight.

Beyond that, both metrics come into play at important parts during the pre-roll production process, from curing, to grinding, and, according to the science, smokeability.

How Water Activity and Moisture Content Affect the Grind

As we always say, it all starts with the grind. And both water activity and moisture content influence the behavior and quality of cannabis flower during grinding, affecting both usability and product integrity.

Cannabis with ideal water activity of between 0.55–0.65 grinds smoothly, producing evenly sized particles. If water activity is too high, the flower may clump together, making grinding difficult and uneven. Buds that are too wet can also jam the blades, causing your grinder not to work properly.

On the other side of the spectrum, water activity that is too low means over-dried flower that breaks apart easy during the grind, resulting in excessive trichome losses and leading to diminished potency and terpene content.

As for moisture content, cannabis in the optimal range (8–12%) retains enough pliability to grind without excessive crumbling. If moisture content is too low, the flower becomes brittle and dusty, leading to uneven grinding and a loss of cannabinoids and terpenes.

Meanwhile, excessive moisture content can also lead to clumping during the grind, making it harder to achieve a consistent particle size.

How Water Activity and Moisture Content Affect Pre-Roll Production

Proper moisture levels make better pre-rolls. Flower that is too dry creates a product that will burn fast and hot, while flower that is too wet may clog grinders and cone-filling machines or simply not pack very well, leading to pre-rolls that burn unevenly or canoe.

Proper moisture content and water activity is also crucial when using automated pre-roll machines. Automated machines are finnicky and require a consistency of inputs in order to work properly. Only well-ground material of a similar particle size can be used in automated machines.

Additionally, the clumping caused by high moisture content can carry over to cone-filling as well, leading to inconsistent pre-rolls and other filling issues that can stall your production process, leading to lost time and lost revenues.

Moisture content also affects the weight of cannabis flower, with wetter flower weighing more. Inconsistent weights, even within the same particle size, can lead to inconsistent pre-rolls and potentially even land you on the wrong side of state regulations surrounding weight variances.

And though water activity does not directly play into weight, cannabis with water activity below 0.55 loses more weight due to evaporation during storage and processing than cannabis within the proper range.

How do Water Activity and Moisture Content Affect Smokeability?

This is where we get into the data from the Science of Smokeability study. This study is a first-of-its-kind, peer-reviewed scientific assessment of how various cultivation and production techniques affect the product from the consumer standpoint.

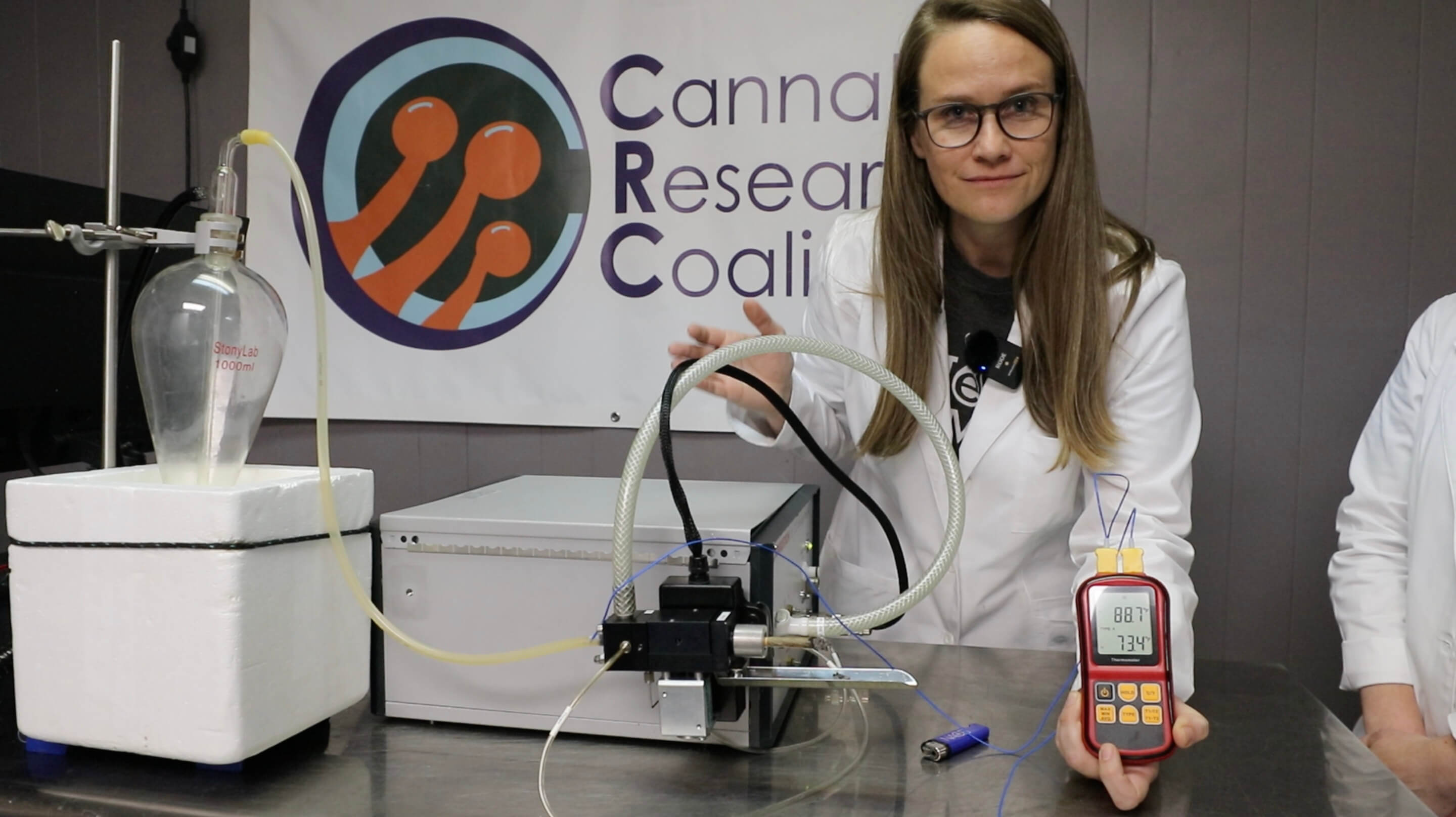

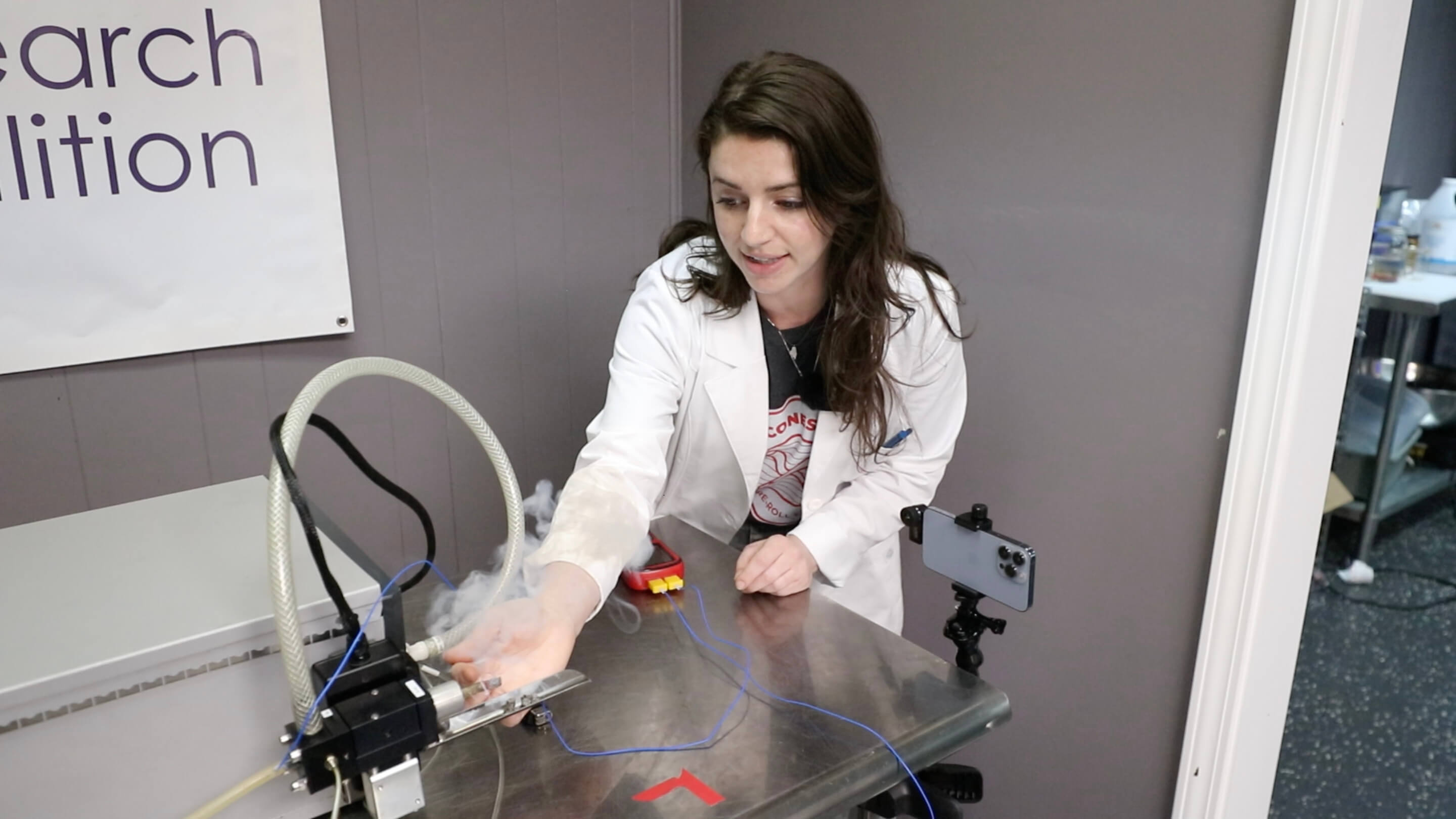

This multi-year research project, spearheaded by Custom Cones USA and the DaySavers brand in partnership with the Cannabis Research Coalition and The Network of Applied Pharmacognosy (NAP), aims to revolutionize our understanding of cannabis cultivation, processing and consumption.

To reach its conclusions, the Science of Smokeability uses a combination of both laboratory research involving a smoking machine and instruments to measure various components of the smoke, and a survey of consumers that tested pre-rolls sent out by scientists. Together, the results give us a wider and fuller look at how different production and cultivation variables play out in the finished, consumer version of products.

Led by Dr. Allison Justice and Dr. Markus Roggan, known for their groundbreaking work in exploring the hypotheses behind the color change of ash in cannabis smoking, the first phase of the study looked at water activity and moisture content.

Using digital hygrometers, high quality hemp pre-rolls were stabilized at three different water activity levels: 0.45 aW, 0.65 aW and 0.85 aW. All three were analyzed using the laboratory’s smoking machine, a Combustion Smoke Analyzer SCS and all but the 0.85 aW pre-rolls (which could be breeding grounds for molds and microbials, making them unsafe for consumption) were also sent to smokers in airtight containers to be smoked as part of the survey. Survey participants were paid for their answers.

According to the results, pre-rolls with a water activity of 0.65 aW produced the highest cannabinoid concentration in the smoke, followed closely by the 0.45 aW pre-rolls. The 0.85 aW pre-rolls, on the other hand, had cannabinoid contents of only 30% of the those in the 0.65 category.

Testing for terpenes – which give cannabis its distinctive smell and flavor – generated similar results, with the 0.65 aW pre-rolls delivering the highest terpene content, with the scientists noting that it suggests “stronger water activity-dependent effects for terpene transfer” in the lower range, though the 0.85 aW pre-rolls again delivered lower terpene amounts overall.

As for results of the survey, there was no statistical difference between aromatic and flavor profiles of the 0.45 and 0.65 aW pre-rolls, however the 0.45 aW pre-rolls produced “a more irritating experience” for smokers, presumably a harsher smoke due to drier weed.

The study also delves into what moisture content and water activity can mean for the bottom line between flower with a water activity of 0.45 aW vs 0.65 aW, which corresponds to a moisture content of about 5% and 9%, respectively. According to the scientists, that difference comes out to about 18.14 grams per pound of flower.

“At an assumed market price of $1.50 per gram, this weight differential represents an estimated revenue loss of $27.20 per pound for material at the lower water weight,” they write.

Is This an Issue for Other Industries Too and How do They Handle It?

And it’s not just the cannabis industry, water activity and moisture content are critical metrics across multiple sectors, each serving distinct purposes in quality control, safety, and product stability.

In the food industry proper water activity helps control mold growth and extends shelf-life. It also influences taste, texture, aroma and color. For example, lower water activity prevents spoilage and helps maintain crispness in snack foods.

For pharmaceutical companies, measuring water activity helps not only prevent microbial contamination and helps reduce risks like caking or clumping in pills and powders, but also ensures consistency between component parts of things like pill capsules.

Even in our industry, paper production, controlling moisture content is key to preventing defects and ensuring uniform texture. Not only that, but it helps us ensure that our cones won’t support microbial growth and pass the same testing regiment as your flower.

Controlling moisture content is even more important for pre-rolled hemp wrap products like blunts, rely on water molecules for their strength and can become brittle when they dry out. It’s why we developed our hybrid hemp cones and tubes that use more hemp fiber and remain pliable even in dry conditions and why we always recommend storing hemp wrap products in a humidor to retain moisture, or at least using a humidor to reacclimate your hemp wraps before filling.

The industry that provides the best case study here might be the coffee industry, where, like cannabis, water activity and moisture content affect weight, quality, safety and shelf-life of the product, particularly in green coffee beans.

When harvested, coffee cherries, as they’re called, have a moisture content of between 30 and 40% and must be dried to about 10-12% for safe storage and transport, while water activity must be reduced to no more than 0.55 to prevent mold growth. Once processed, the biggest threat to coffee quality during this stage is inconsistent moisture content, which can trigger changes in the bean that degrade flavor and introduce defects.

It’s the water in the bean that provides a medium for the chemical reactions that creates coffee’s complex flavors and aromas. During roasting, moisture content drops to approximately 1-3% and water activity decreases to between 0.20 and 0.35, which locks in the flavors and extend shelf-life. Even the rate of moisture loss directly affects the flavor profile.

This whole process is much like curing cannabis buds post-harvest. How fast moisture is removed and how dry you let your buds get affect the flavor, potency and smokeability of your product.

How Water Activity and Moisture Content are Measured

So how do they measure moisture content and water activity?

Moisture content is determined by weighing a sample before and after evaporating its water content using heat. The difference in weight provides the moisture percentage.

Water activity is assessed using a specialized meter that calculates the vapor pressure ratio between the sample and pure water under identical conditions.

Both of these measurements are best done in a laboratory to get the most precise and accurate results, but they can be approximated relatively inexpensively.

To measure moisture content, weigh a cannabis sample using as precise a scale as possible, then place the sample in a low-temperature oven – about 176 degrees Fahrenheit or 80 degrees Celsius until it becomes dry and crispy, but not burnt. Then, reweigh the sample. To get the moisture content, subtract the dry weight from the initial weight, divide that number by the initial weight and multiply by 100.

You can also use a wood moisture meter set to “softwood.” Though that will not be perfectly accurate, it should provide consistent readings for comparison.

Or, you can buy a bench-top moisture analyzer, which will provide accurate numbers, but do cost more.

Water activity, however, requires a specialized meter to assess vapor pressure equilibrium in a sealed chamber and is difficult to replicate in DIY form, though a hygrometer placed in a sealed container will approximate the results, as relative humidity corelates with water activity values.

Final Thoughts on Water Activity and Moisture Content

Understanding water activity and moisture content, as well as the relationship between them, is essential for producing safe, stable, and high-quality products - whether we're talking about pharmaceuticals, food, coffee or cannabis.

While moisture content tells us quantity, water activity reveals quality - specifically how water interacts within a product. Together, these measurements provide a comprehensive approach to quality control, leading to better flower, a smoother production process and, ultimately, higher-quality pre-rolls.

If you’re not paying attention to the water activity and the moisture content of your flower and your pre-rolls, you could be costing your company money and sending your customers to a fresher, more flavorful and more potent competitor.