What Type of Labels Should I Use for my Pre-Roll Tube?

Posted by Custom Cones USA on May 24th 2019

As a pre-roll company, you can easily make or break the brand you are trying to build by not taking the proper steps for labeling and packaging your pre rolls. You want your customer to know whose pre roll they’re buying, right? You could have the best pre-roll in the world, but a doob tube with a plain label will just not be as appealing as a competitor with better packaging. There are many options for labels; some options include Vinyl, Paper, Foil, and BOPP (Biaxially Oriented Polypropylene).

I recommend using the BOPP style labels, for a few reasons. They do exactly what their mission is - STICK, and really well if you ask me! Probably its most notable trait is its variable transparency, meaning your stickers can take of the appearance of glass, paper or even metal! It is also a clean material to print on. It is a low toxicity material that most food and hygiene companies rely on for use in their products. They are also durable, resistant to solvents, acids and oils.

Be weary of the Avery white film labels, because they are known to not hold up very well and peel off doob tubes with tight radiuses. Like most things in life, you get what you pay for. I would not recommend going the cheapest route because chances are it’s going to cost you more to re-label your defective pre-roll packages than it would to just get some solid quality labels from the start. You definitely want to make sure your labels are meant for small circular packages, because a label that sticks well on a flat surface won’t adhere properly to a tight, narrow tube.

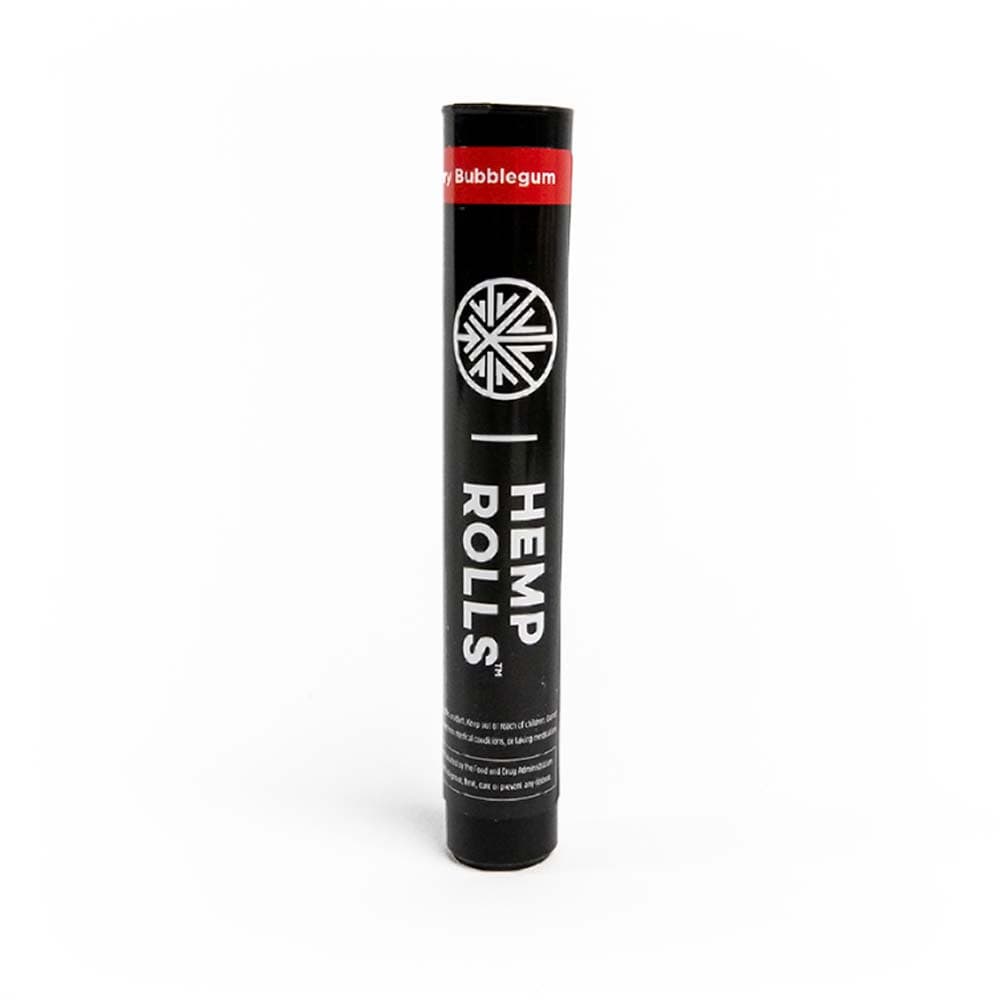

Another idea to consider is how large the labels will be. If you like to show off your product in a clear tube, it’s advised to consider the size of the label in comparison to the size of the pre-roll container. For most standard sizes, I recommend leaving an inch of space open so that you can see the pre-roll through the tube and also leave room for a barcode if needed. If you want to cover the whole product, you can either get a solid colored container or print a label large enough to wrap around the entire tube.

Once you have the type of label you want picked out and your label designed, the next step is to apply it. There are a few different ways you can go about applying your stickers. Of course, there is the tried and true manual way, but as you scale your business and sell more pre-rolls, you may want to look into automation. To automate your process, you can order one of a few pre roll labeling machines. From small to large scale and from semi-automatic to fully- automatic pre roll labeling machines, there are many possibilities to execute a smooth pre-roll packaging process.

A commonly forgotten idea that will make a huge difference, no matter what type of label or printer you use is cleaning your tubes. I highly advise, at the very least, blowing off your tubes with compressed air. If you are storing your pre roll tubes near the production facility, chances are some of the flower dust will get on the tubes and this will prevent the labels from properly adhering. If you want a guarantee for no peel stickers, I recommend a quick wipe down with isopropyl alcohol. You wouldn't paint your house without washing the walls first would you? I can't tell you how many times I've been disappointed by a well rated product simply because of the labels peeling off.

This may seem like a bunch of technicalities to look out for in the pre-roll production process, but who doesn’t want to top their competition and gain a loyal following from their consumers? Quality and mindfulness is key – but remember to still have fun when creating your pre-rolls, put good energy into the production and enjoy your time producing something great. Your customers will feel the difference!

There are many options for labels; some options include Vinyl, Paper, Foil, and BOPP (Biaxially Oriented Polypropylene).